Numerical Investigation and Cause-and-Effect Chain Analysis of Cyclic Variations and their Effect on Knocking Combustion

Introduction

Knocking combustion in an internal combustion engine is initiated by auto-ignition ahead of the flame front. Thus, knocking combustion is determined by the regular combustion process initiated by a spark plug and the auto-ignition in the unburned mixture. The latter directly depends on the local thermo-chemical state and results from (global and local) mixing. Under certain conditions, auto-ignition causes characteristic high-frequency pressure oscillations. To avoid this knocking combustion, the engine is usually operated under non-optimal conditions, which limits the efficiency. The investigation of knocking combustion is very challenging due to the high complexity. Experimental studies are accompanied by highly-resolved simulations to enable a cause-and-effect chain analysis of knocking combustion.

Methods

Multi-cycle engine LES are performed incorporating an in-house code based on the OpenFOAM framework, which manages mesh creation, mesh motion and topological changes. At first, a non-reactive cycle is simulated to initialize a subsequent reactive cycle. The tracking of the auto-ignition process starts in the second subsequent reactive cycle. The combustion process is simulated by a flame surface density approach (FSD) coupled to tabulated chemistry based on the flamelet-concept. Auto-ignition is modeled by an extension of the generalized Knock Integral Method - which is a precursor model - and uses a tabulation of the auto-ignition progress.

Results

This phase of the HHLR project is aiming to establish the framework for multi-cycle LES of combustion under knocking conditions. Several multi-cycle LES of a single-cycle research engine are conducted. In particular, the operating conditions focus on the knock limit and incorporate surrogate fuels with stochiometric homogeneous mixture resulting from port fuel injection. The joint analysis of LES and experimental results enables a cause-and-effect chain analysis of local and global influences on the auto-ignition process.

Discussion

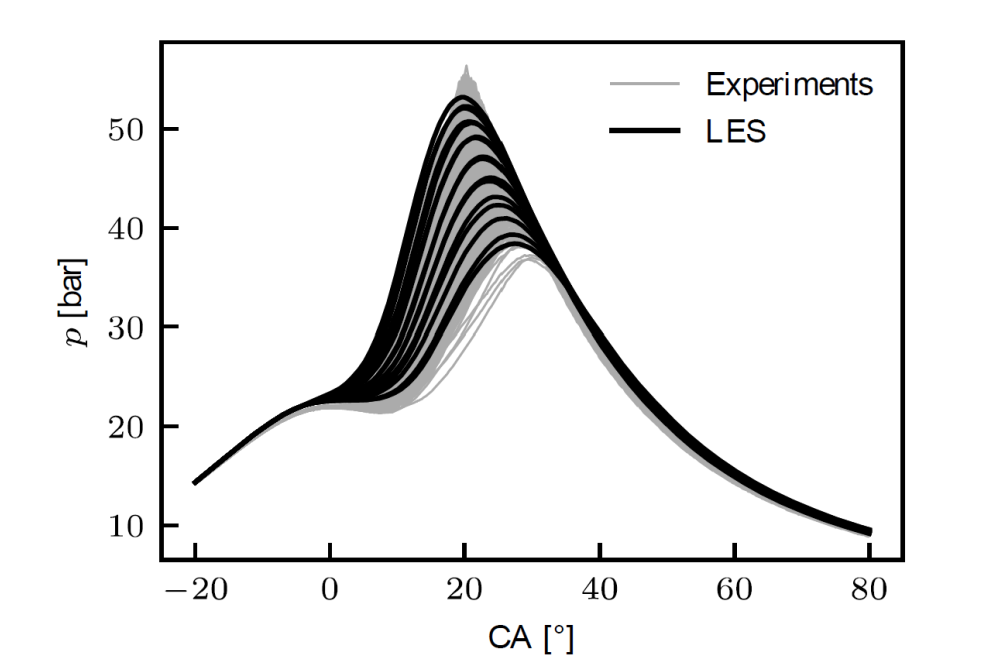

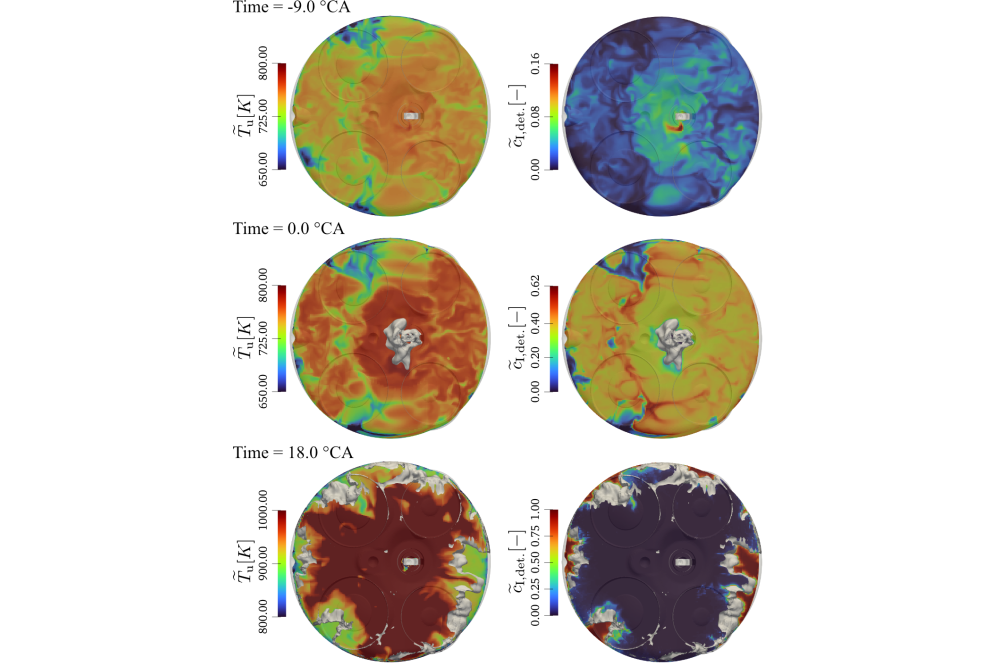

With a multi-cycle LES, the combustion of a multicomponent Toluene Reference Fuel (TRF) in a single-cylinder research engine is investigated under knocking conditions. The combustion modeling is able to capture the pressure traces observed in the experiments (cf. Figure 1). The fuel exhibits a negative temperature coefficient (NTC) regime, which affects the local auto-ignition process in the unburned mixture. A widespread two-stage auto-ignition occurs (cf. Figure 2). The engine LES enables the detailed investigation of the influence of temperature stratification and flame propagation on the auto-ignition process and thereby extends the findings of the experimental campaign.

Outlook

The future investigations will incorporate different fuels and operating conditions as well as more cycles to further investigate local and global influences on the auto-ignition process.