Investigation of Iron Dust Flames in a Channel

Introduction

Iron powder offers a clean and sustainable pathway for heat and power generation and has the potential to replace conventional hydrocarbon-based fuels. It can be combusted and subsequently recycled using renewable energy sources such as wind and solar energy. However, a comprehensive understanding of iron particle combustion remains incomplete, and several challenges must be addressed to enable the design of efficient and safe combustion devices. In this project, we investigated two key aspects: flame propagation inside a channel and variation of inter-particle distances. These phenomena were studied using boundary-layer-resolved (BLR) simulations of iron particles, incorporating the heterogeneous reaction between iron and oxygen. Depending on operating conditions, iron dust flames may propagate either in a continuous mode, where neighboring particles burn simultaneously, or in a discrete mode, where particles ignite individually in a percolatingwave manner. This complexity highlights the need for experimentally validated numerical models to accurately capture and analyze the underlying combustion physics. Because iron powder combustion can involve several hundred particles, access to high-performance computing (HPC) resources was essential to perform simulations on highly resolved computational grids.

Methods

In this project, boundary-layer-resolved (BLR) simulations involving up to 2,100 particles confined within a channel were performed. The unsteady governing equations for flow, species transport, and energy were solved using second-order accurate discretization schemes. To assess their influence on flame propagation, different wall boundary conditions were systematically examined. A heterogeneous combustion model for iron particles was implemented and applied at the particle surfaces, effectively enabling direct numerical simulations (DNS) of iron dust combustion. The availability of high-performance computing (HPC) resources on the Lichtenberg cluster made it possible to simulate such large particle numbers through efficient parallelization.

Results

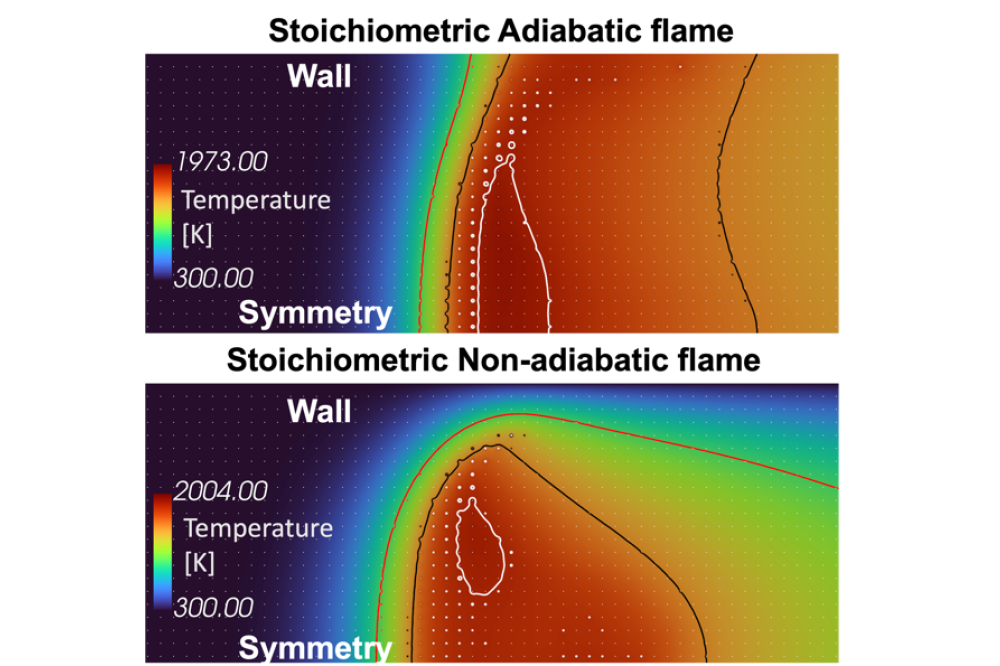

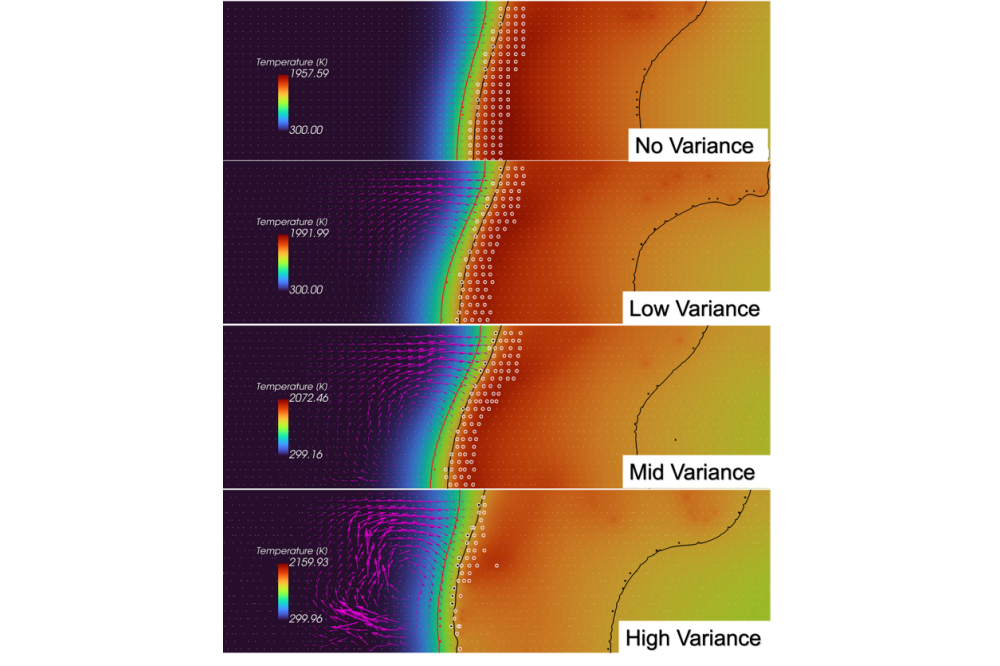

During this project, boundary-layer-resolved (BLR) simulations of iron dust flames propagating inside a channel were conducted. The three-dimensional symmetric computational domain consisted of both regular and irregular particle arrangements, with ignition initiated at one end of the channel. Computational grids containing up to 13 million cells were employed, and particle positions were systematically varied. The influence of wall boundary conditions on flame propagation was investigated, leading to an improved understanding of the mechanisms governing iron dust flame propagation.

Discussion

This project on propagating iron dust flames has yielded several key insights. Specifically, rich iron dust flames propagate stably in a continuous mode, governed by oxygen depletion, which leads to the simultaneous combustion of multiple neighboring particles. In contrast, lean iron dust flames exhibit unstable propagation behavior due to the rapid combustion of individual particles in environments with higher oxygen availability. Furthermore, under lean conditions, flame clusters may form and propagate independently from neighboring clusters. The study also reveals that when inter-particle distances are varied while maintaining a constant global equivalence ratio, iron dust flames display distinct propagation behaviors. In particular, large variations in inter-particle spacing result in some flame regions propagating in a discrete mode, while others propagate in a continuous mode. Additionally, irregular inter-particle spacing can induce vortex structures that redistribute oxygen along the flame front. The results further indicate that iron dust flame propagation in channels differs significantly from that of gaseous flames. Notably, near the walls, iron flames can utilize excess oxygen present in the quenching region associated with non-adiabatic wall conditions. Moreover, in cases with irregular inter-particle spacing, flames may propagate at different local speeds despite a constant global equivalence ratio.