Atomistic Simulations of the Grain Boundaries Mobility and Defect Influence on the Magnetic Materials

Introduction

Understanding the sintering behavior of nanoparticles has become crucial, due to high surface energy and surface-to-volume ratio at the nanoscale significantly influence atomic diffusion. This project investigates the grain boundary (GB) migration behavior and defect evolution during the sintering of Fe₅₀Ni₅₀ nanoparticles using atomistic simulations. At the nanoscale, GBs play a critical role in controlling densification, microstructural evolution, and mechanical stability of sintered materials. Using molecular dynamics (MD) simulations, this study explores how GB mobility and defect structures such as dislocations and stacking faults contribute to sintering at varying temperatures and particle sizes. High-Performance Computing (HPC) resources enabled tracking atomic-scale phenomena across a range of thermal conditions to understand how grain boundary kinetics drive defect creation-annihilation and material densification.

Methods

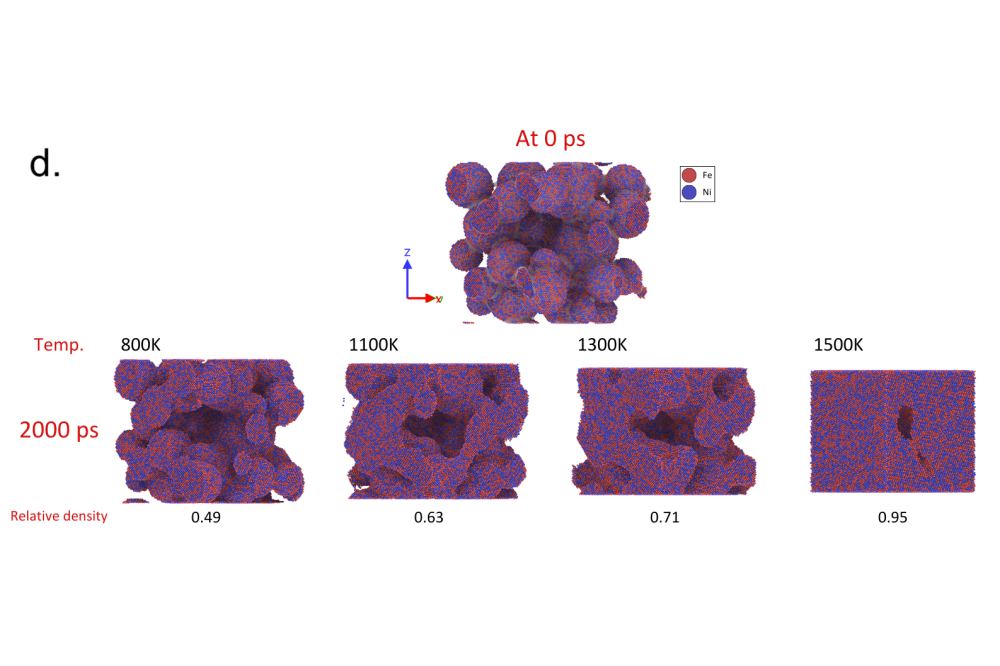

Simulations were conducted using the LAMMPS software with the embedded-atom method (EAM) potentials suitable for the Fe-Ni binary system. Spherical nanoparticle configurations ranging from 2 to 10 nm in diameter were generated. Simulations were performed along the [100] crystallographic direction under both isothermal and ramped heating conditions, ranging from 800 K to 1600 K. Structural analysis was conducted using OVITO with Polyhedral Template Matching (PTM), radial distribution function (RDF), and dislocation extraction analysis (DXA). In multi-particle setups, periodic boundary conditions and NPT ensembles were applied to replicate bulk-like behavior. Relative density evolution was calculated using Delaunay tessellation techniques.

Results

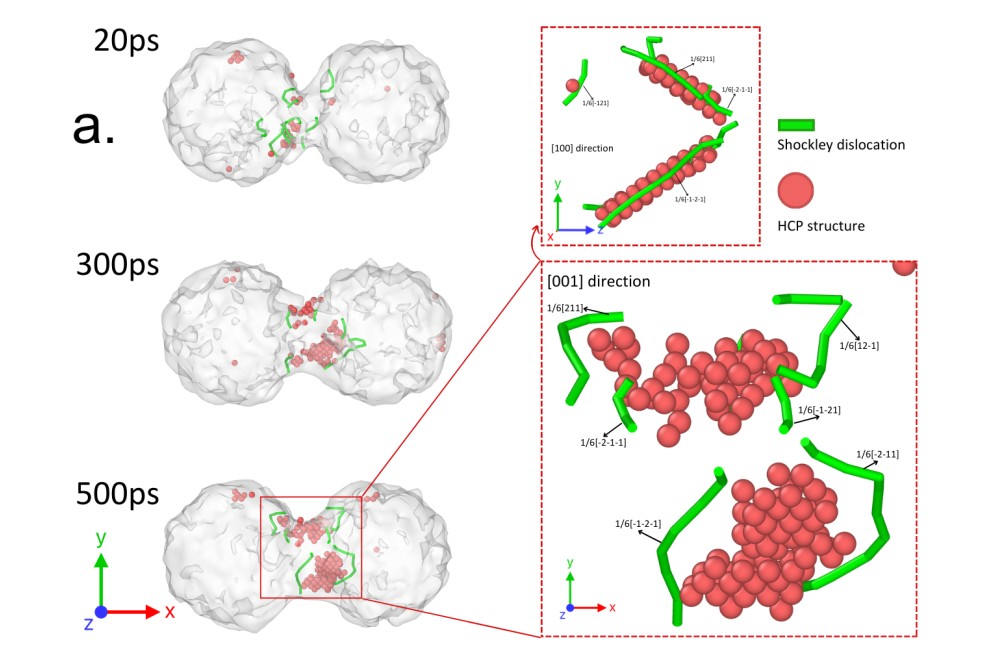

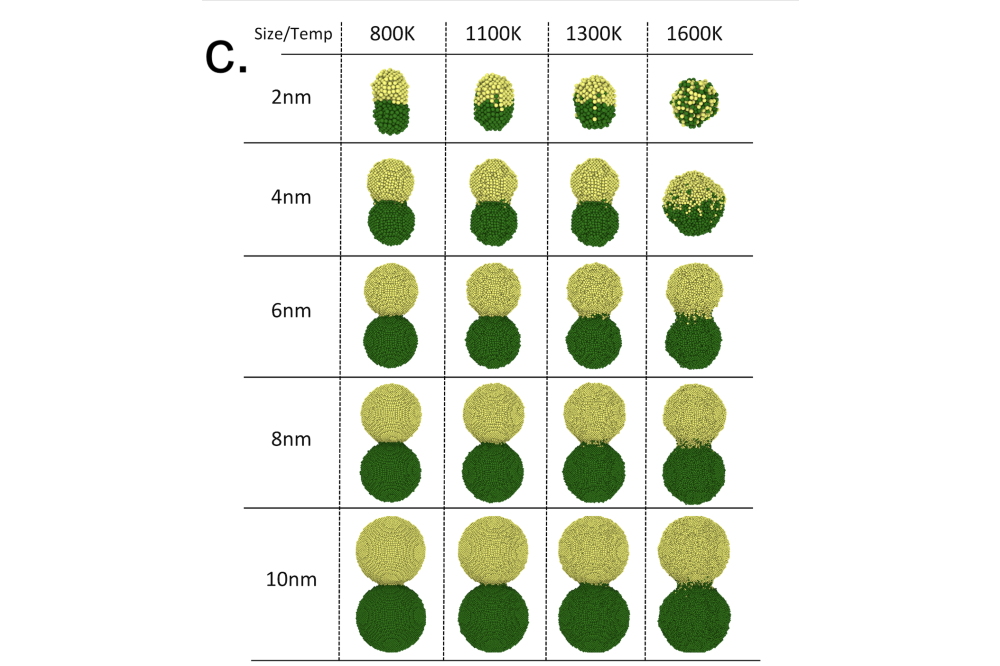

Grain boundary migration is temperature-dependent forming when two particles connect under sintering stress. At lower temperatures (800 - 1100K), GBs remains largely immobile due to insufficient atomic mobility. As temperatures exceed 1100 K, GB mobility increases sharply driven by enhanced atomic diffusion and capillary forces for 6nm particles. This behavior was observed at even lower temperatures for smaller particles due to sharper curvature. The mobility scales non-linearly with temperature reflecting a bulk activation temperature. Dislocations and stacking faults emerged near GBs due to stress concentration and thermal mismatch under sintering stress. In smaller particles (2 nm), GBs annihilate rapidly as particle coalesce whereas in larger particles, complex GB networks form. With increase in particle size, sintering is dominated by defect-assisted GB sliding and migration. The simulations showed dynamic defect evolution: GBs tend to form under sintering stress when particles form a contact with each other, and dislocation networks form and interact dynamically with migrating grain boundaries, becoming increasingly dense and complex as the sintering neck grows and temperature rises. Stacking faults are formed near the GBs, while the GBs are disordered, and higher temperatures promoted dislocation annihilation and sharp coalescence of particles leading to densification.

Discussion

Grain boundary migration is temperature-dependent forming when two particles connect under sintering stress. At lower temperatures (800 - 1100K), GBs remains largely immobile due to insufficient atomic mobility. As temperatures exceed 1100 K, GB mobility increases sharply driven by enhanced atomic diffusion and capillary forces for 6nm particles. This behavior was observed at even lower temperatures for smaller particles due to sharper curvature. The mobility scales non-linearly with temperature reflecting a bulk activation temperature. Dislocations and stacking faults emerged near GBs due to stress concentration and thermal mismatch under sintering stress. In smaller particles (2 nm), GBs annihilate rapidly as particle coalesce whereas in larger particles, complex GB networks form. With increase in particle size, sintering is dominated by defect-assisted GB sliding and migration.