Reinforcement of High-Entropy Metallic Glasses: A Molecular Dynamics Study

Introduction

Since their invention in the 1960s, metallic glasses (MGs) gained great attention due to their high strength and elastic limit compared to their crystalline counterparts. They are produced by quenching alloys from the melt fast enough to prevent crystallization. However, the lack in crystalline order leads to severe brittleness at room temperature, since the carriers of plastic deformation are shear bands (SBs) and not dislocations like in crystalline alloys. SB propagation can be hindered by the introduction of additional interfaces such as crystalline precipitates – nanocrystals (NCs) – in the glassy matrix1,2. Another materials class, which is similar to nanocrystals, are bulk nanoglasses (NGs), which are produced by consolidation of glassy nanoparticles3. For them, large plasticity compared to the homogeneous bulk MG is reported for instance in Ref.4,5. In this work, we investigated reinforcement mechanisms in a new type of MG, which consists of at least five components in near-equiatomic proportion, a so-called high-entropy metallic glass (HEMG). Our model system is comprised of the elements CoCrFeMnNi. Its crystalline form, the famous Cantor alloy6, is characterized by remarkable fracture toughness and strength7 as well as low-temperature ductility8 compared to conventional alloys. Therefore, the combination of the two, a HEMG-NC nanocomposite, seems a promising materials combination with super-high hardness9 and high strength and ductility10 compared to the conventional polycrystalline Cantor alloy. Our results reveal, that the MG remains stable against the nucleation of NCs. Artificial interfaces need to be introduced instead, but here the failure mechanism depends delicately on the relaxation state of the interfaces. Overall, our results give insights into deformation mechanisms of novel high-entropy nanocomposites.

Methods

All simulations were performed using molecular dynamics (MD) as implemented in the open source software package LAMMPS11. MD is a computer simulation method based on solving Newton’s equations of motion numerically. The forces and energies are calculated based on an interatomic potential for CoCr- FeMnNi parameterized by Choi et al12. Postprocessing was performed using the open source visualization tool OVITO13.

Results

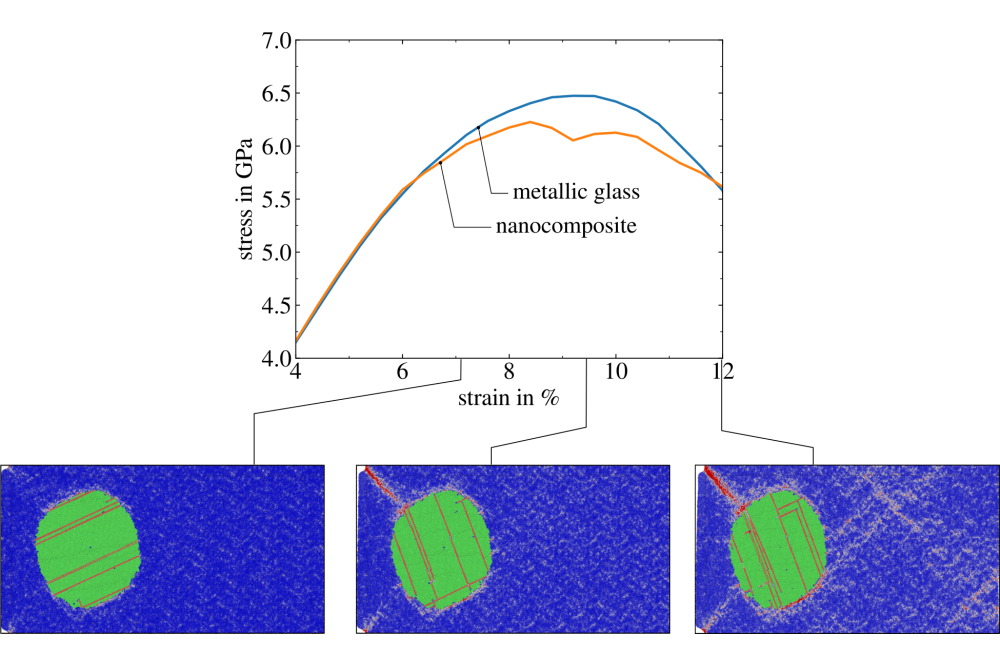

For the production of the MGs, melt quenching of a 49,000 atoms sample with dimensions 83 × 83 × 83Å3 was performed with a rate of 0.1 K s−1. Annealing slightly below and above the glass transition temperature was performed to induce nucleation of crystalline precipitates. However, even after 2 μs no crystalline phase was observed despite the large driving force, i.e., difference in energies of glassy and crystalline state. Therefore, artificial interfaces were introduced as described above. However, despite careful compaction up to 99% density (compared to the MG) or annealing the strength of the NGs and NGCCs was well below the strength of the MG. Already before deformation, the grain-grain interfaces were defective due to the compaction. Therefore, we directly inserted a crystalline, spherical inclusion of about 40 nm diameter into the glassy matrix, which was enlarged by replicating the initial MG precursor to a sample of 120 × 50 × 57 nm3. Here, dislocations nucleated from the interface, even before the SB hit. Another SB nucleated from the interface only after a second glide system was activated in the precipitate, indicating a cutting mechanism. This suggests, that a crystalline precipitate inserted into the glassy matrix indeed acts as an obstacle to SB propagation.

Discussion

The absence of a crystalline phase in the HEMG after long-term annealing might be an effect of the small size of the simulation cell, the short physical time accessible via MD and the high interface energy between glassy and crystalline phase. However, due to time constraints we could not pursue these possibilities further. The NGs and NGCCs produced by consolidation of glassy or crystalline nanospheres seemed promising at first but for the defective interfaces. Here, annealing of the samples could be performed prior to deformation to rejuvenate the highly sheared regions. Finally, the role of a spherical NC as SB obstacle could not be investigated here in greater detail due to the high computational costs. More careful relaxation of the interface might have prevented the early nucleation of stacking faults at the interface. The interface’s relaxation state seems to be the decisive factor here, since the Cantor alloy exhibits a negative stacking fault energy.