Numerical Investigation of Drop Impact, Coalescence and Evaporation on Superheated Surfaces VI

Introduction

Spray cooling is a very effective method for cooling of electronic devices. The study of the impact of single and coalescing drops onto a superheated wall contribute to a better understanding of the complex fluid dynamics and heat transfer mechanisms during spray cooling. Special consideration is given to the three-phase contact line, where solid, liquid and vapor meet and high evaporation rates are observed. Accurate calculations of the fluid dynamics and heat transfer require large computational effort.

Methods

The governing equations of the numerical model describe the conservation of mass, momentum and energy for incompressible fluid flow. Heat and mass transfer at the liquid-vapor interface is accounted for in source terms. To track the interface, the volume-of-fluid method is used. A sub-grid model accounts for fluid dynamics and heat transport mechanisms on a microscale in the vicinity of the three-phase contact line. The results from this sub-grid model are implemented in the form of correlations in the overall numerical model.

Results

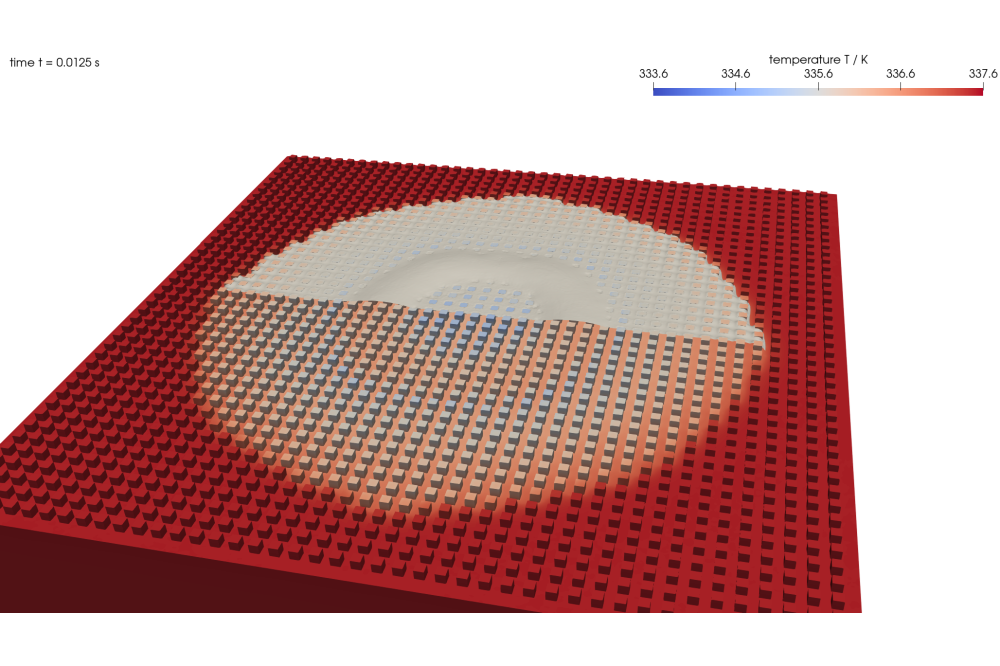

Texturing of the wall surface can significantly enhance the heat transfer compared to a smooth wall. Thus, the drop impingement onto textured, supereheated walls is investigated. In particular, regular arranged rectangular pillars with different sizes and arrangement are studied.

Discussion

Just after the impact, the drop spreads over and around the pillars. At the end of the impingement process, the liquid height is equal to the pillar height and small puddles on top of pillars evaporate quickly. Pillars prevent the drop from receding, resulting in a large wetted area during the sessile drop phase. This significantly increases the heat flow, especially for small pillars, compared to smooth walls. The highest heat flow occurs during the spreading phase, as cold liquid rapidly wets the hot wall, causing a significant temperature decrease, especially on the pillars. The pillars extend both the wetted area and the contact line, which enhances heat transfer compared to smooth walls. During the sessile drop phase, the relative contribution of the contact line evaporation in the total heat flow is twice so high as in the case of a smooth wall. Generally, small and low pillars with narrow gaps are most effective for heat transfer. The maximum drop spreading on textured walls depends on the pillar size and arrangement. Low and small pillars increase the spreading, while high and large pillars reduce it. The sessile drop shape depends on the pillar configuration: small pillars with narrow gaps yield circular shapes, high pillars with wide gaps yield square shapes and octagonal shapes occur in between. These shapes result from differing flow resistance and capillary spreading along and diagonal to the pillar rows. The liquid volume does not affect the sessile drop shape as the pillar size is the determining factor. The maximum wetted area decreases and shifts to later times with lower impact velocities, but the wetted area during the sessile drop phase remains unaffected. Higher impact velocities lead to greater total heat transport due to increased convective heat transfer during the spreading phase. The sessile drop shape changes from square to circular with decreasing impact velocity due to varying flow resistances between and along the pillars.