Numerical Investigation of Drop Impact, Coalescence and Evaporation on Superheated Surfaces V

Introduction

Spray cooling is a very effective method for cooling of electronic devices. The study of the impact of single and coalescing drops onto a superheated wall contribute to a better understanding of the complex fluid dynamics and heat transfer mechanisms during spray cooling. Special consideration is given to the three-phase contact line, where solid, liquid and vapor meet and high evaporation rates are observed. Accurate calculations of the fluid dynamics and heat transfer require large computational effort.

Methods

The governing equations of the numerical model describe the conservation of mass, momentum and energy for incompressible fluid flow. Heat and mass transfer at the liquid-vapor interface is accounted for in source terms. To track the interface, the volume-of-fluid method is used. A sub-grid model accounts for fluid dynamics and heat transport mechanisms on a microscale in the vicinity of the three-phase contact line. The results from this sub-grid model are implemented in the form of correlations in the overall numerical model.

Results

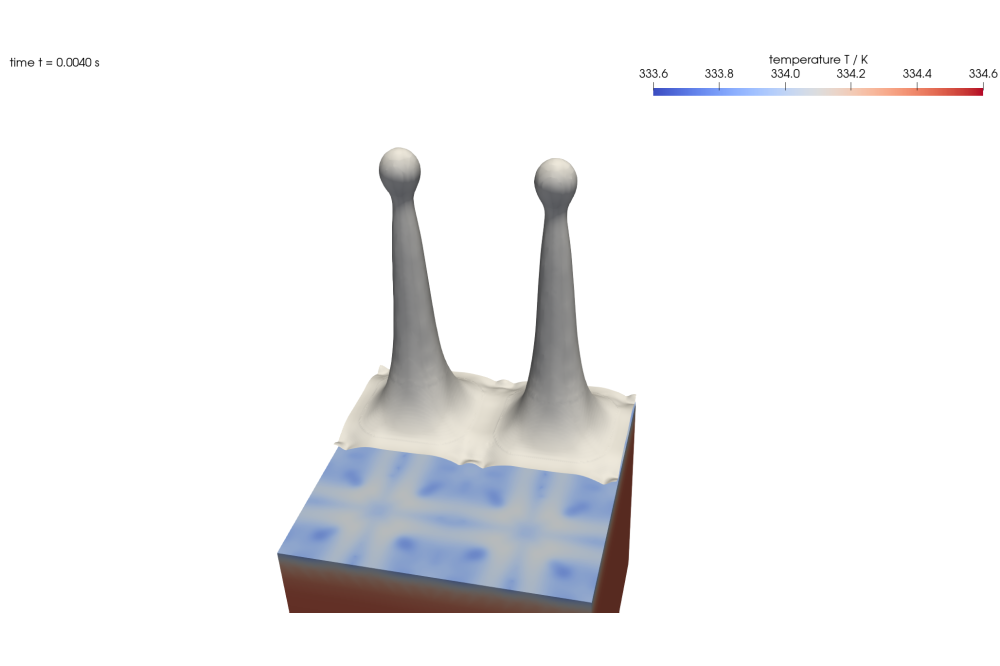

The solver is used for three different configurations of drop impingement onto smooth, superheated walls. The first study addresses the simultaneous impingement of two drops with varying horizontal distance between the drops. Second, the non-simultaneous impingement of two drops with varying time interval between the drops is addressed. Finally, the periodic drop array impingement of drops with varying horizontal distance between the drops is investigated.

Discussion

When two adjacent drops hit a superheated wall, a semi-lunar liquid sheet forms between their impact points. This sheet is straight during simultaneous impingement but inclines toward the first drop in non-simultaneous cases. The sheet’s height increases as the drop distance decreases. During the spreading of the drops, the liquid rim of the drops not taking part in the coalescence process behaves like a spreading single drop, but coalescence influences the behavior in the receding of the drops. Coalescence reduces both the wetted area and heat transfer compared to two non-interacting drops. As the interaction between drops increases (i.e. the distance decreases), both the maximum wetted area and maximum heat flow decrease. At the end of the impingement process, a single sessile drop forms. As the time interval between the drops increases, both the maximum wetted area and the maximum heat flow decrease and shift to later times. However, the total heat transfer at the end of the impingement process is only slightly affected by the time interval. A short time interval between the drops results in the highest heat transport. The heat transfer at the contact line is significant during the receding and sessile drop phases, although it transfers less heat compared to two non-interacting drops due to its shorter length. The numerical model can predict the experimentally observed temporary coalescence at a large distance and a small time interval, although this occurs at slightly higher wall superheat in simulations compared to experiments. A dynamic contact angle model is essential for predicting drop separation. Generally, drop separation improves heat transfer. In drop array impingement, a thin film forms at small and medium drop distance, while individual drops form at larger distance. The total heat transfer increases with increasing distance between the drops. However, at a medium distance the highest average wall heat flux is predicted due to the thin film formation. A large distance between the drops leads to dry spots on the wall, detrimental for cooling, and reduce the average heat flux. Additionally, an uprising liquid jet is observed at small distances, which is not seen with two drops impacting under equal conditions.