Parallel Finite Element Methods for Complex Flows of Complex Fluids

Introduction

The objective of this ongoing project is the continuous development and advancement of effective simulation methods for unsteady fluid flow problems and their application to real-life engineering problems. Common ground for the subprojects presented below is our in-house parallel finite element solver for multi-physics problems, including compressible and incompressible Navier-Stokes flows, linear elastic materials, non-Newtonian fluids, as well as thermal and scalar transport problems.

Methods

The in-house FE solver XNS is written in Fortran and C and utilizes an MPI parallelized framework. The machine learning applications are employed in two in-house frameworks. One of them is built up on the Deep-XDE python package and leverages automatic differentiation integrated in TensorFlow to evaluate differential operators. In the PINN algorithm, the residuals of both the governing partial differential equations (PDEs) and boundary constraints are incorporated into the loss function which is minimized during the training of the neural network. For more complex problems we use a domain decomposition approach, where two or more neural networks are trained in parallel. The second framework is developed from scratch, using functionality provided by PyTorch to train the neural networks.

Results

In the subproject Compressible Two-Phase Flows in Moving Domains XNS was used to simulate oil films in a compressible air flow. It was extended with a workflow to enable automatic adaptive mesh refinement using the library mmg.

In the subproject Physics-Informed Neural Networks for Flow Field Prediction in Stirred Tank Reactors, we constructed two-dimensional models capable of accurate predictions for velocity and pressure within a range of Reynolds numbers.

Within the subproject Precision Melt Engineering (SFB 1120), high-precision 2D simulations of the injection molding process have been performed. These simulations have been successfully compared to experimental results. Furthermore, to investigate the requirements for efficient, and yet accurate simulations, a mesh study has been performed.

In the subproject Multi-strand Fused Deposition Modeling Simulation, we developed a framework in our in-house fluid solver to study the multi-strand fused deposition modeling simulation. The novelty of this approach is that we use a spline-based boundary description to include the effect of previously printed strands in the simulation.

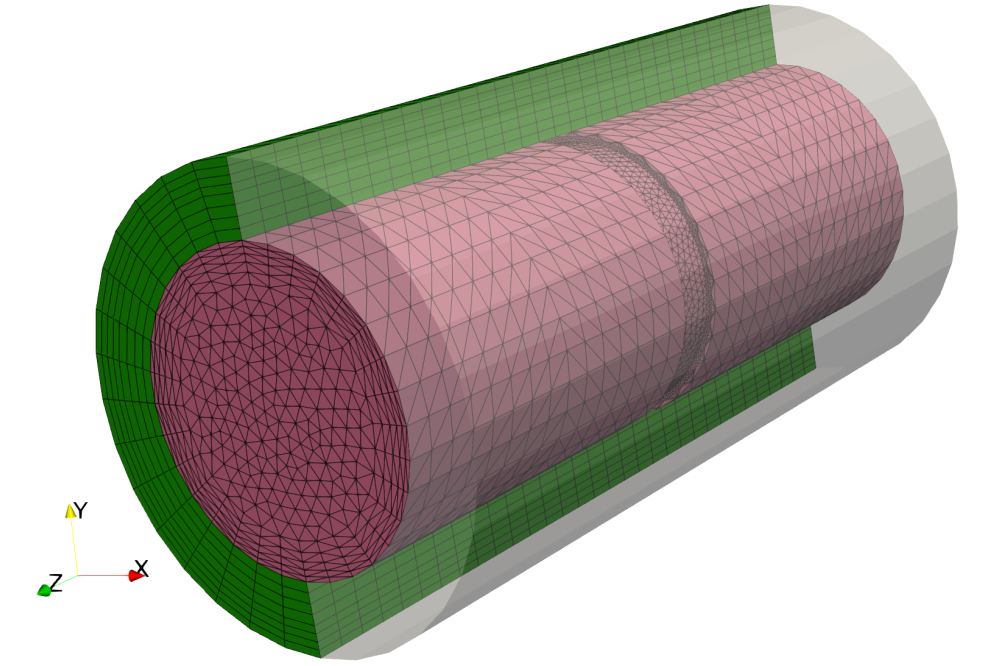

Within the subproject In-Stent Restenosis in Coronary Arteries, we coupled a multiphysics model for in-stent restenosis to hemodynamics and drug elution in stented arteries. We tested our approach on a simplified artery segment with ring stent. The growth model is implemented in the solid solver FEAP and for the fluid model we use the in-house code.

Discussion

The simulations of compressible two-phase flows gave some insights to the leakage path of oil in internal combustion engines with late-post injection. The two-phase flow model will be extended to simplex based space-time finite element discretizations, and the parallel scaling behaviour on Lichtenberg II will be compared to the previously used discretization with prismatic elements. Further efforts on reducing the computational time of these simulations will include the use of simplex-based space-time finite element discretizations. Furthermore, we plan to apply the gained knowledge to 3D simulations. After having identified the most promising methods for improving the prediction accuracy of PINNs for stirred tank reactors in a 2D test case, we will proceed to extend the model to a realistic 3D geometry.

The multi-strand simulation of fused deposition modeling allowed the study of porosity, which is a crucial macroscale property in objects built by 3d printing technology. We plan to extend the study to different deposition strategies, such as aligned, skewed, and crossed layers.

In the subproject on in-stent restenosis in coronary arteries we plan to expand the model to more complex and patient-base geometries.