Unsteady Modeling and Simulation of Oxy-Fuel Combustion Chambers

Introduction

To reduce the C02 footprint of the current energy and transport sector, hydrogen has become one of the most promising alternatives to conventional fossil fuels due to net-zero carbon emissions. Also, hydrogen seems chemically simple, it exhibits substantially different combustion behaviors compared to conventional fuels when burnt in gas turbines. Hence, predictive numerical methods are required to design and optimize future propulsion systems. In this work, a flamelet-based tabulation method well established for hydrocarbons is extended for the application to hydrogen to account for its distinct properties. Taking into account detailed chemical kinetics and therefore allowing for a detailed representation of the flame’s microstructure at reduced computational cost make flamelet-based tabulation approaches such as the flamelet-generated manifold (FGM) a commonly used method for turbulent combustion simulations. However, there has been little focus on analyzing such models for fuel blends, including hydrogen. One reason for that is the challenging inclusion of differential diffusion effects into FGM, which may become crucial for highly diffusive fuels such as hydrogen. To assess the predictive capabilities of the extended methods, a laboratory-scale burner will be investigated which is highly relevant for industrial applications. The laboratory-scale burner is operated with a stratified hydrogen-methane flame, which is thoroughly investigated. The main objective of this study is to assess the model’s capabilities to predict flames with hydrogen addition, a necessary feature in the next few years during the transition to pure hydrogen combustion. Such models are essential for future propulsion systems’ efficient and safe design.

Methods

Within this project, numerical simulations are conducted with the research code FASTEST. The code is used by several institutions in the context of computational fluid dynamics. Within our framework, it has been extended to compute chemically reacting flows in complex geometries efficiently. The finite volume code uses a block-structured boundary fitted mesh consisting of arbitrarily shaped hexahedrons. The filtered Navier-Stokes equations are solved in a low-Mach number formulation with second-order accuracy in space and time.

Results

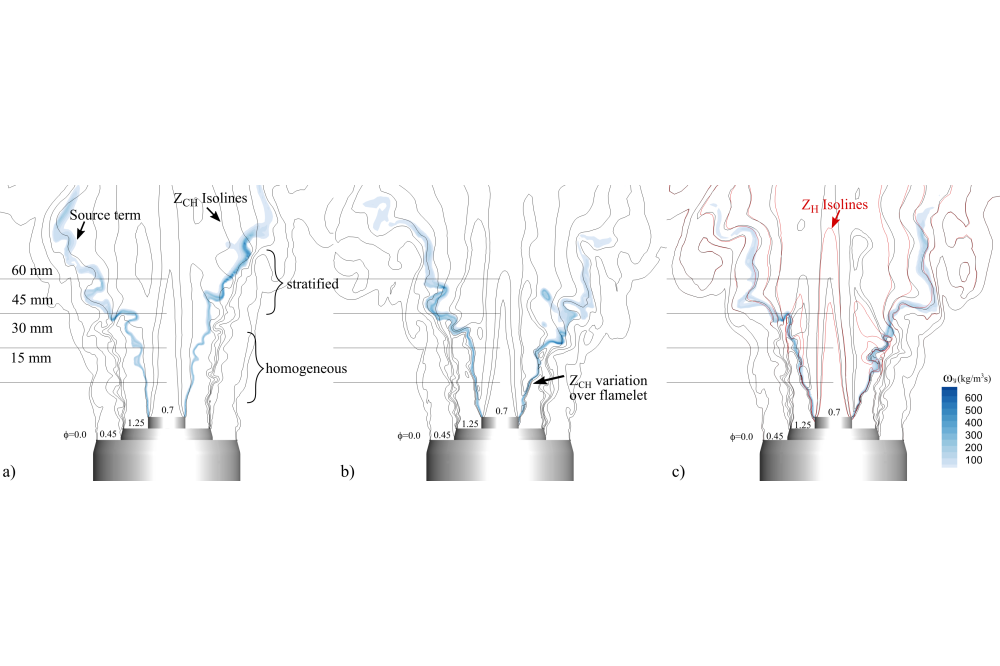

In this work an extension of the FGM approach that takes into account differential diffusion to assess the importance of differential diffusion for methane hydrogen blends was developed. To this end, an extended model containing five controlling variables can be derived. However, the high correlation of certain controlling variables and the number of control variables could be reduced to three controlling variables in this study. These models are coupled to the artificially thickened flame (ATF) approach to facilitate large-eddy simulations (LESs). To ensure the consistency of the coupling between FGM and ATF when differential diffusion is considered, the model is thoroughly verified and validated using freely propagating and stratified laminar one-dimensional flames. Finally, simulations of the turbulent premixed stratified burner operated with a hydrogen methane blend are performed. The validation of the modeling framework is performed by comparing the simulation results to extensive experimental data, allowing an in-depth analysis of the macro- and microstructure of the flame. The introduced models differ by the number of control variables used to parametrize the table. Thereby, the influence of physical effects (e.g., heat losses), represented by a particular control variable, can be analyzed separately.

Discussion

First, the extended models taking into account differential diffusion were derived, verified, and validated in canonical flames. Subsequently, LES simulations were conducted of the Darmstadt stratified burner operated with a H2 / CH4 blend. The extended models performed well near the burner exit in regions with predominantly homogeneous premixed combustion for the turbulent stratified burner. Furthermore, it was demonstrated that two controlling variables are sufficient to reproduce the first two moments of the experimental data in this regime. This means that neither heat loss effects nor the high diffusion velocity of H2 significantly influences the macrostructure of the flame. While the macrostructure was predicted accurately by assuming unity Lewis numbers, the analysis of the H2 mass fraction in composition space revealed that, especially in the stratified regions, differential diffusion effects play a role and must be considered to take into account the hydrogen diffusion correctly. Again, the introduction of a second mixture fraction to take into account the high diffusion velocity of H2 improved the results significantly.

In future works, the proposed two mixture fraction model that takes into account differential diffusion effects should be applied to configurations containing higher shares of hydrogen where even stronger differential diffusion effects are expected. Furthermore, practically relevant configurations operated with different operating strategies, such as dual fuel injection, should be investigated.