A Study on the Influence of Inclusions in Solid Electrolyte in Li-Ion Battery System

Introduction

Despite the technological advancements that have been made in the field of electric vehicles, the development of batteries still has a long way to go before they can exhibit their maximum potential. Due to the phenomenon of capacity fading and the time it takes to fully recharge, the world is currently looking for new materials that can improve the performance of batteries. One of the most common factors that can affect the performance of batteries is the crack formation within them. This phenomenon can lead to loss of capacity and durability, as well as affect the performance of electric vehicles. Understanding the various properties of batteries can help scientists develop new ideas on how to improve their technical capabilities. Here, we developed a Multiphysics fracture model to study the degradations mechanisms in all-solid-state batteries.

Methods

A thermodynamically consistent multi-physics framework consisting of chemo-mechanical behaviour in all-solid-state Li-ion batteries is developed. The model studies the degradation behaviour in cathode active materials. An advanced cohesive phase-field damage model is implemented for studying the propagation of fracture in active materials during its lifetime. Apart from the standard phase-field model, the cohesive phase-field (CPF) model differs with its definition of crack topology function and damage function. The main idea behind this method is to consider the evolution of the energy loss in the standard phase-field formulation due to the different fracture regimes. For instance, the Griffith’s brittle fracture and the Dugdale’s or Barenblat’s cohesive fracture. Therefore, the cohesive phase-field fracture model can be considered as almost length-scale independent regarding the crack path and overall system activity[1].

Results

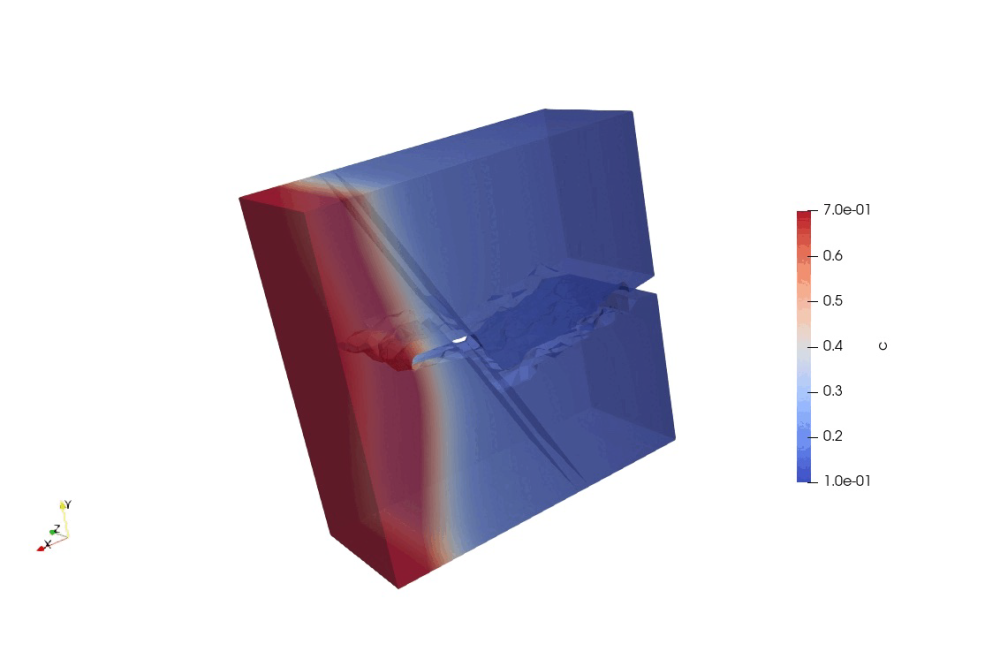

A chemo-mechanically coupled cohesive phase-field fracture model is developed and used to study the degradation behaviour in battery active materials. We studied the effect of phase transition upon chemical loading/unloading of cathode materials. There were significant changes in the degradation behaviour in both cases. Also, the model is used to perform fracture propagation in polycrystalline active materials both in 2D and 3D RVEs.

Discussion

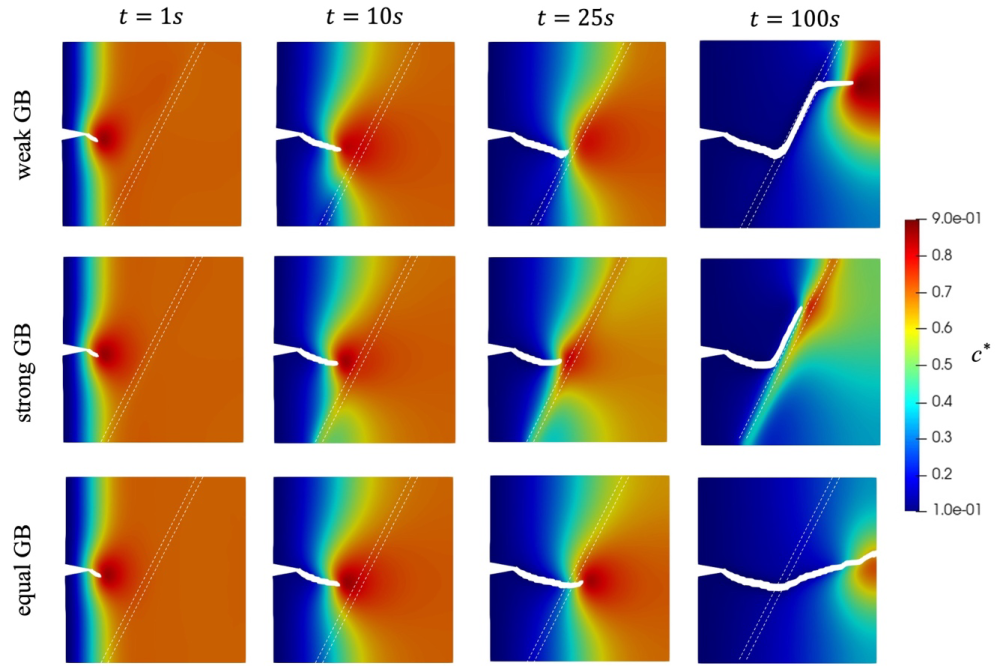

We compare the damage profile for the three cases with weak, strong and comparable grain boundaries. Here, we found that the initiation of the damage at the pre-notch is almost at the same time and the damage path is also similar for the initial time steps. Since we have defined anisotropy in the material, the cracks tend to travel in particular directions in the grains. When the crack front is near the grain boundary (GB) and due to the variations in the mechanical and fracture properties of the GB, the crack propagation is distinctive in each case. For the case with a weaker GB, the crack gets trapped in the GB and moves through the GB. After some time, the crack tends to deviate from the GB and enter the second grain. However, the anisotropic properties in the second grain are not so evident. While considering strong GB, the crack travels through the first grain in the given preferential crack direction. However, when the crack front is near the GB it deviates to another direction in the same grain itself. Due to the strong mechanical and fracture properties of the GB, it restricts the crack from entering the GB. But, to release the stored energy the crack deviates and travels through the same grain till the end time. Considering the case of comparable GB, there is no difference between the chemical, mechanical and fracture properties of the grains and GB. Although, due to the presence of anisotropy effect there is deviation in crack paths from the straight line. We also found that there is higher concentration accumulation at the tip of the cracks. Also, in the case of strong GB, we see that the GB is under severe tensile stress.