Influence of Mixing Processes on the Performance of High-Pressure Polymerization II

Introduction

At industrial scale low-density polyethylene (LDPE) is produced at pressures up to 3000 bar in autoclave or tubular reactors. Lab scale experiments are often carried out in single zone stirred vessels. Comparing typical lab-scale and industrial scale autoclave reactors, the latter have a higher height-to-diameter ratio and multiple reaction zones what leads to a different residence time behavior. In the previous project period, the connectivity between mixing and polymer properties was shown. Therein, the goal is motivated to build a laboratory reactor that closer resembles an industrial multi zone autoclave. Hereby, a major part is to design a suitable stirrer that ensures a fast mixing of the feed and a clean separation into three reaction zones.

Methods

Different stirrers are evaluated by CFD (Computational Fluid Dynamics) with the commercial software Ansys Fluent (Release 2021 R1). Continuity, momentum, and turbulence (k-ε) equations are solved stationary. The multiple reference frame (MRF) model is used to account for the stirrer rotation. After the steady-state flow field has been formed, a transient species transport equation for a tracer is solved. Thermo-physical properties of the fluid and the tracer are assumed to be similar and are calculated based on empirical correlation as a function of temperature, pressure, and polymer content.

Results

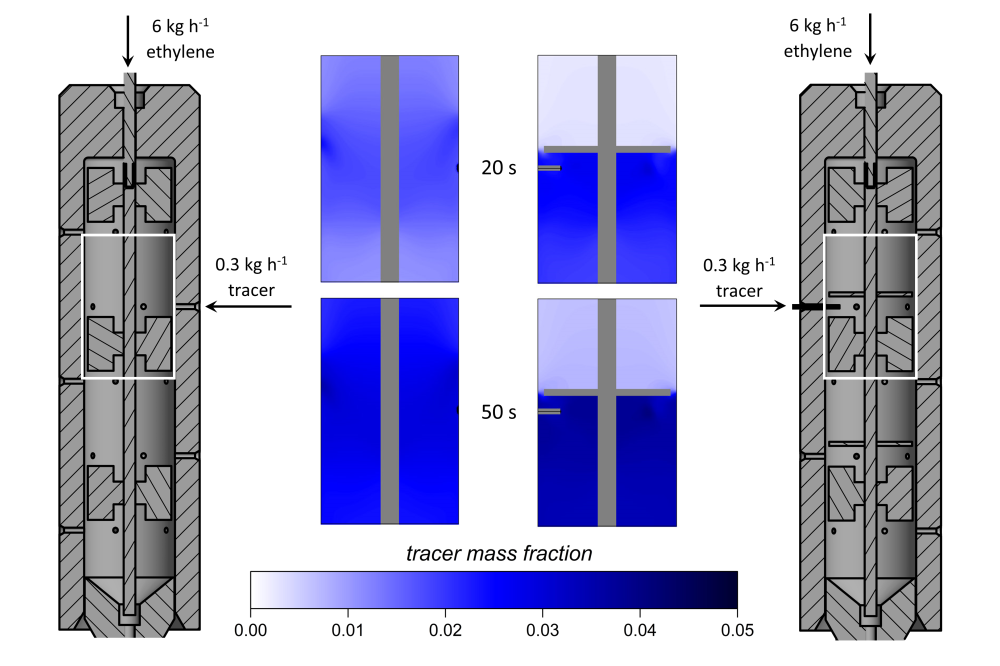

The stirrer design is limited by the fact that polymer systems tend to build fouling layers. Hence, only removable internals are allowed and wall baffles, as common in stirred vessels, cannot be installed. Therefore, a horizontal disc is attached to the stirrer shaft, to achieve a division into three reaction zones. It should be ensured, that additional comonomer or initiator does not mix up with the previous zone. The diameter of the disk is varied to have on one hand a good separation and on the other hand prevent blocking in the gap between disk and wall. The quality of the zone separation is tested by simulating the transient distribution of a tracer fed sideways to the second zone. In Figure 1 a comparison between a stirrer with and without horizontal disk is shown. In the final design, the disk has a diameter of 91 % of the vessel diameter. Additionally, the feed position is moved below the disk by inserting a small capillary. Thereby, a good separation of the zones is achieved over more than 50 s which is well above the mean residence time of around 30 s in each reaction zone.

Discussion

A stirrer to divide the reaction room of a high-pressure autoclave reactor into multiple reaction zones is successfully developed. Up to now, the influence of the polymerization reaction inside the autoclave onto the thermo-physical properties and thus on the residence time is neglected. The knowledge and the implementation of the kinetic mechanism from the previous project period can be transferred to the new reactor geometry. Furthermore, the new three-zone autoclave is to be compared to the existing single zone reactor as well as to industrial reactors.