Chemical Looping Gasification for Sustainable Production of Biofuels (CLARA)

Introduction

Project CLARA aims to develop Chemical Looping Gasification (CLG) technology from lab scale to industrial scale. CLG can be used to produce liquid fuels as well as base chemicals from biogenic and municipal residues. CFD simulation helps in understanding the processes inside of the reactor, which often cannot be measured experimentally.

Methods

The CFD model was developed in ANSYS Fluent based on the Euler-Lagrangian approach. To reduce computational effort several real world particles were lumped together creating an equivalent particle called parcel. Interaction between particles and walls were modelled using the discrete element (DEM) approach. The hydrodynamic model is based on an “energy minimization multi-scale” approach to improve the particle entrainment and to get more realistic results for solid circulation.

Reaction modelling was done using a reduced reaction network. Kinetics were mainly taken from experimental analysis within the project with some taken from literature. Reaction kinetics were implemented in the model using “user defined functions” (UDF).

Results

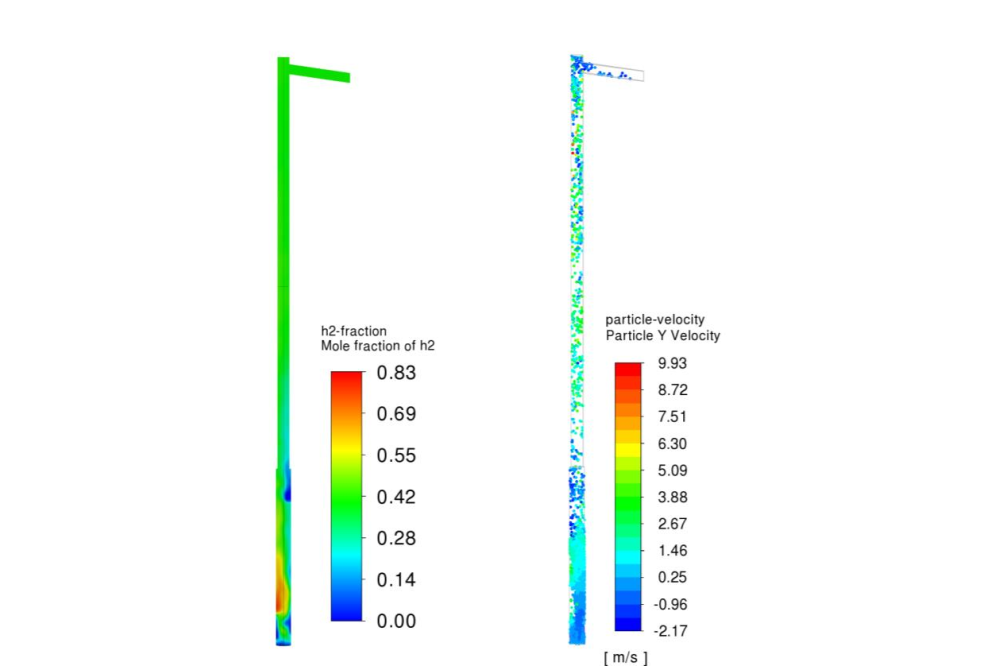

Simulation of lab scale and industrial scale CLG reactors were successful. Validation was done for the lab scale reactor. The pressure loss over the reactor, which is one of the key parameters in fluidized bed hydrodynamics, could be predicted accurately with the developed model.

However solid circulation was overestimated in the simulations.

The reaction model also showed good agreement for most solid and gas phase species except for Hydrogen which was overpredicted while carbon dioxide was underpredicted.

Discussion

The overprediction of the solid circulation has been reported in literature and is a common problem for DEM simulations. For this reason the EMMS drag model was introduced which improved the simulation behaviour somewhat. There are several approaches in literature for more accurate drag models, however those were outside the scope of this project.

The overprediction of Hydrogen can be attributed to several factors. First the fraction and conversion degree of solid fuel in the reactor during steady state is not known as no such samples can be taken during experiments. This creates an uncertainty in the boundary conditions. Secondly the experimental kinetics have been developed using powdered fuel as well as single pellets while inside of the reactor the conditions are much more complex.

Further investigations are needed to assess the deviation of kinetics between laboratory tests and reactor conditions.