Multi-Scale Modeling of Additive Manufactured Magnetic Materials

Introduction

In 2018, Gottschall et al. proposed a multi-stimulit concept for magnetocaloric cooling. [1] The energy consumption related to cooling is expected to increase significantly over the next decades. Therefore, a more energy efficient and environmental friendly alternative is needed to satisfy the increasing demand. In the multi-stimui concept, the application of magnetic field is complimented with the application of mechanical stress to control the first-order phase transition, e.g. in Heusler alloys. Simulating the multi-stimuli concept using a micromagnetic phase-field model is supposed to support the development of a magnetocaloric cooling device by calculating the potential temperature change ΔTad within the multi-stimuli concept and for simulation of the heat exchange.

Methods

The Object Oriented MicroMagnetic Framework (OOMMF) code is used to perform purely micromagnetic simulations, utilizing the finite-difference method. For the finite-element implementation of the proposed micromagnetic phase-field model, the open source Multiphysics Object Oriented Simulation Environment (MOOSE) framework is used. Purely mechanical FEM simulations are performed using ABAQUS.

Results

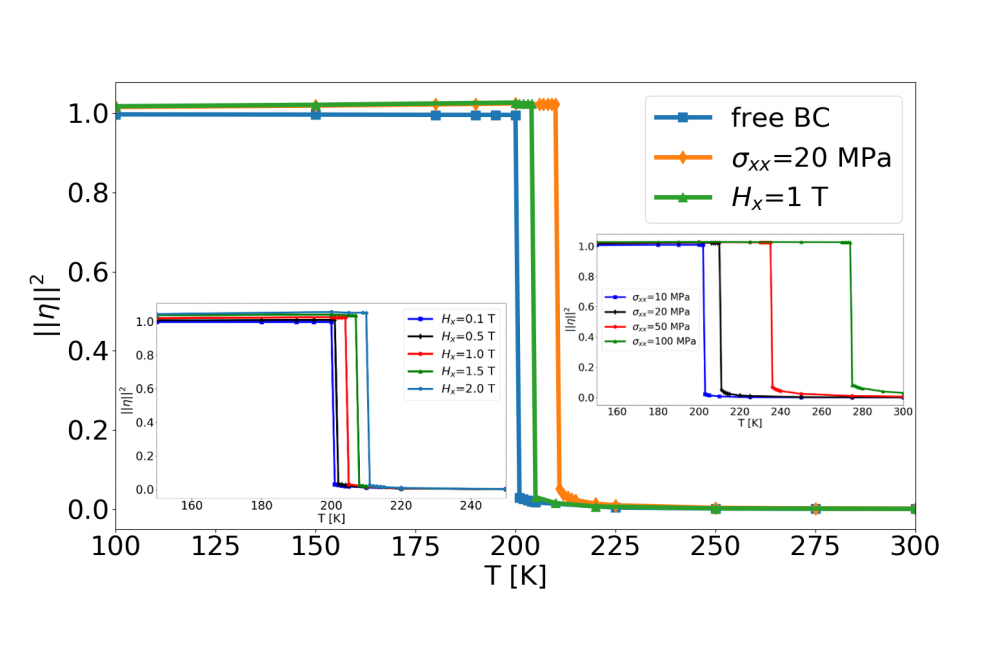

We propose a phase field model based on Landau theory to simulate the magnetic domain evolution during the martensite formation in, e.g., Heusler alloys. The model is capable of capturing the magentic martensite transformation, as well as the magnetic martensite to non-magnetic austenite transition. Using temperature-dependent coefficients for the 2-3-4 Landau polynomial and modifying the micromagnetic formulations, the phase transition can be captured. Our proposed model is also capable to capture the shift of the phase transition with applied magnetic field and stress. For the magnetic to non-magnetic transition, we obtain shifts of the transition temperature towards higher temperatures, which is in agreement with experimental results. The application of the external stimuli stabilizes the magnetic martensite phase.

Discussion

The model is shown to be capable of capturing the magnetic martensite state as well as the mangetic martensite to non-magnetic austenite transition. In the martensitic state, the proposed micromagnetic phase-field model is capable of reproducing multi-domain structures with the corresponding magnetic domain microstructure. The transformation of the martensite microstructure with applied stress and magnetic field is captured as well. The three-dimensional, finite-element implementation allows for the investigation of geometry and boundary condition dependent microstructures. In addition to the martensitic state, the modification of the micromagnetic formulations allows for the simulation of the magnetic to non-magnetic phase transition. Application of stress and magnetic field stabilizes the magnetic phase, shifting the transition temperature towards higher temperatures, see Fig. 1.