Analyzing, Comparing and Evaluating Non-Stationary Methods for Oxy-Fuel Configurations

Introduction

The separation of CO2 in oxy-coal combustions is facilitated through firing coal in oxygen (O2) enriched recirculated flue gas, which mainly consists of carbon dioxide (CO2) and water vapor. These significant environment changes have important implications on the combustion chemistry, the mass and heat transfer interaction processes and the radiation, which poses several modeling challenges.

Methods

Reynolds-averaged Navier-Stokes (RANS) simulations are still used commonly for engineering applications. As the high performance computing is continuously increasing, it provides the unsteady simulation methods, especially large-eddy simulations (LES), to gain a significant role in understanding and predicting turbulent reacting flows. LES has proven its applicability and reliability in technical and scientific applications having the advantage of better representation of unsteady flow and combustion phenomena. Detailed investigations are required in order to gain deep understanding of the physico-chemical processes in such complex configurations.

Results

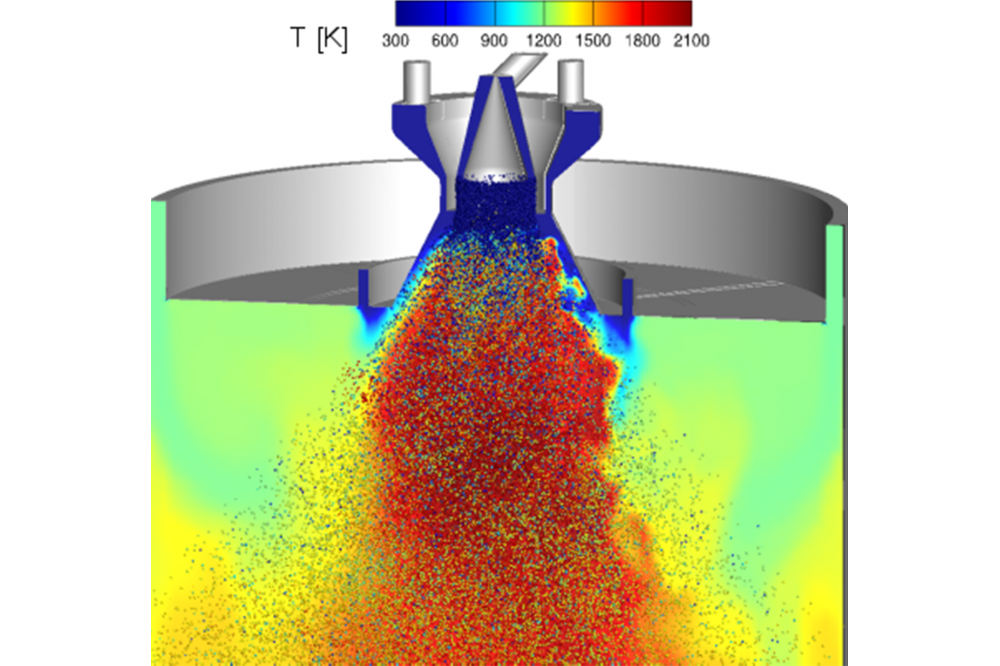

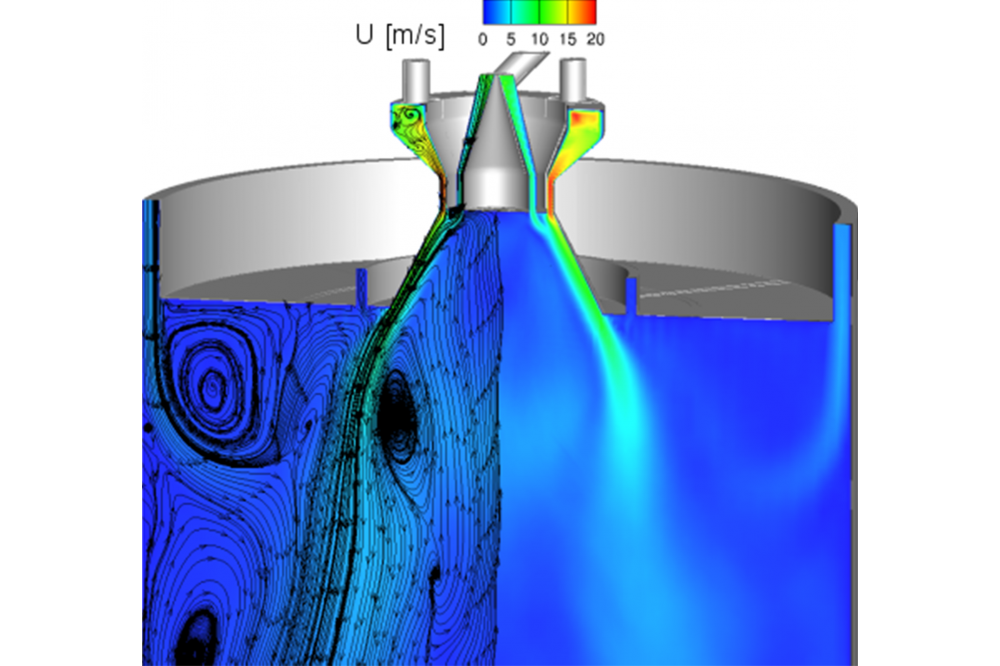

In this study, previous works of residence time analyses were continued this time for reactive conditions. Some larger deviations of the predicted results compared to the experimental data were observed. As the conducted analyses for non-reactive conditions were in good agreement, further studies need to be accomplished. Further, the modelling and simulation of pulverized oxycoal combustion in a downward-fired semi-industrial swirl burner configuration were part of this study, where a flamelet model and an Euler-Lagrange two-way coupling approach for dispersed multi-phase flows were utilized. The results have shown good agreement in some species of the combustion products where as some other seems to be underpredicted. Which might be the reason of the char combustion model, which has to be investigated. The figures below show a slice through the domain of the semi-industrial combustor where the velocity magnitude and the streamlines of the average flow field (left) and the temperature field of the continuous and the particle phase (right) is presented.