Numerical Simulation and Analysis of Wetting Phenomena in Inkjet Printing

Introduction

Droplet impingement and spreading are of particular relevance for various technical applications, including inkjet printing. The small length scales of only a few microns, however, pose a limitation to experimental observations. Therefore numerical simulations of droplet impingement, spreading and coalescence are conducted within the scope of this project. Special focus is thereby put on the interaction between heat and species transport processes on one side and the wetting process on the other side.

Methods

To gain a better understanding of the underlying transport processes, numerical simulations of droplet spreading with coupled surfactant transport as well as heat transfer were performed.

Similar to the preceding project periods, the two-phase flow is described using the algebraic volume-of-fluid method implemented in the open source CFD library OpenFOAM. The contact line dynamics are modeled using a hydrodynamic subgrid scale model. Furthermore, the twophase flow solver was extended to account for the transport of soluble surfactants using a two field approach. In addition, our in-house extension for conjugate heat transfer was used to describe the heat transfer between droplets and substrate. By including appropriate surfactant concentration and/or temperature dependent material models, heat and species transport are coupled to the momentum balance. The code employs acceleration techniques such as adaptive mesh refinement and load balancing.

Results

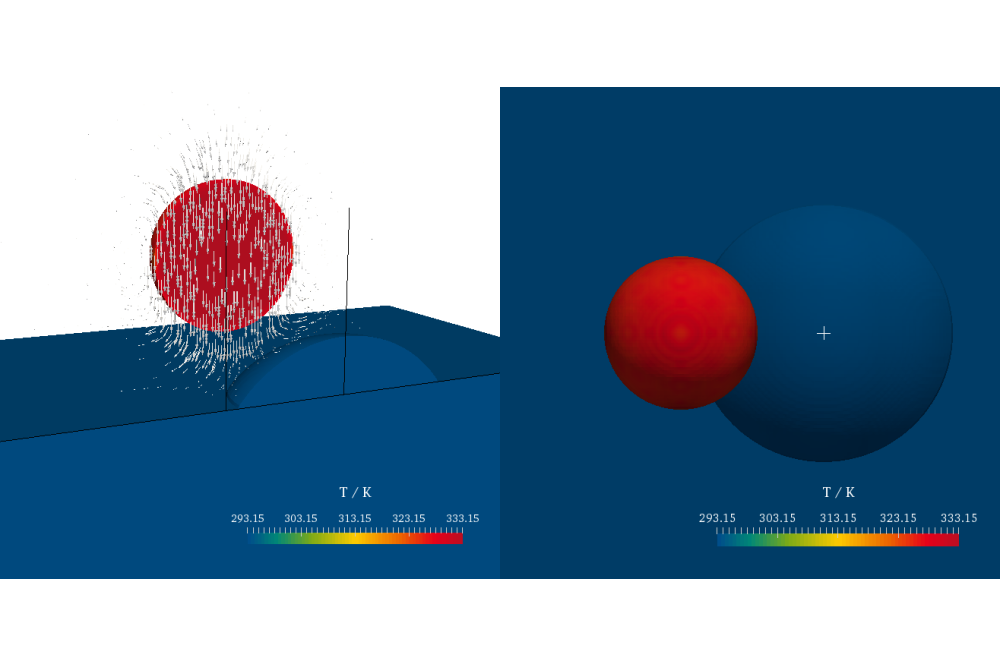

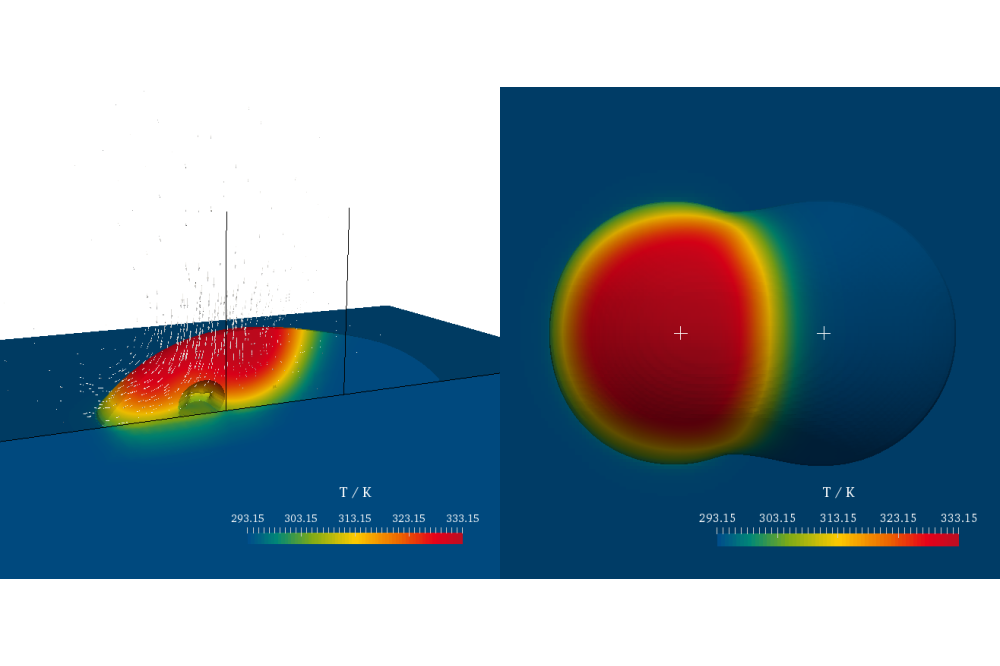

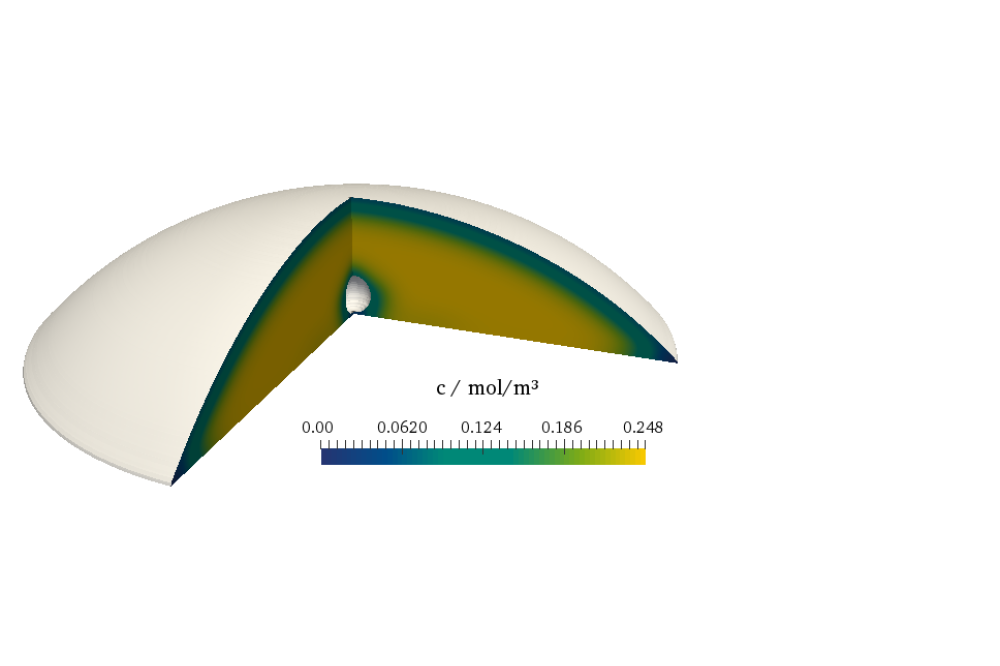

Within the scope of the work of Gründing et al. (2020), the contact line model used within this project for the simulation of droplet spreading was further developed and subsequently evaluated against three different methods for the simulation of multiphase or free surface flows including wetting phenomena. These methods are the geometric volume-of-fluid method, the level-set method and the arbitrary-lagrangian-eularian method. The four numerical methods showed overall good quantitative agreement. The presented results can therefore serve as benchmark solutions for new code developments. Furthermore, the influence of heat transfer on droplet collision was studied. Figure 1 and 2 show the off-centered impact and collision of a pre-heated micrometer sized droplet on a solid substrate with a previously applied droplet. Shortly after impact, the two droplets form a fairly symmetric shape, with an entrained gas bubble at the edge of the first droplet. Even though a temperature dependent viscosity was modeled, the droplets maintain their symmetrical shape as they spread in the following. Also simulations of individual droplets impacting onto a solid substrate at different droplet and substrate temperatures were conducted. The results show overall faster spreading at higher droplet and ambient temperatures. The influence of these temperatures was observed to vary depending on the spreading regime. Several parameters related to surface active substances were varied. Changing the surfactant amount and initial distribution within the droplet resulted in notable differences in spreading behavior. Figure 3 shows the bulk concentration within a spreading droplet. As surfactant adsorbes to the liquid-gas interface, the bulk concentration near the interface decreases. In addition to these studies on individual droplets, simulations of off-centered collision of micrometer sized droplets were conducted. Different surface ages of the surfactant laden droplets resulted in Marangoni-flow along the interface.

Discussion

The results provide insight into the influence of heat and species transport processes on droplet impact and off-centered droplet collision on a solid substrate, as it occurs in inkjet printing. Resolving capillary waves, which is essential to an accurate description of the hydrodynamics of these processes, requires high spatial and temporal resolution of the simulation. In conjunction with the asymmetry of the off-centered collision, this makes the use of a High Performance Computer indispensable.