Gasification Processes with Integrated Surplus Electricity Integration for Flexible Power Generation and Production of Synthetic Fuels from Residual Materials (VERENA) I

Introduction

Project VERENA aims to open new recycling paths for biogenic and municipal residues through different gasification processes. CFD simulation is used to gain a thorough understanding of the processes inside of the reactor as well as scale-up of the process from lab scale and semi-industrial scale to industrial full scale. Due to the large scale of the processes, simulation can only be conducted on a HPC in a reasonable amount of time.

Methods

The CFD model for the fluidized bed gasification is based on a 4-way coupling Euler-Lagrangian model implemented in ANSYS Fluent. Particle interactions are treated with the discrete element method (DEM). Due to the high solid loading in the fluidized bed a coarse-graining approach is used, which uses larger equivalent particles to represent many small particles thus saving computational time.

The gasification reactions are modelled using a reduced reaction network including the main homogeneous and heterogeneous reactions. Reaction kinetics for the heterogeneous reactions were determined in-house with TGA analysis, while the homogeneous reactions were modelled after literature.

Results

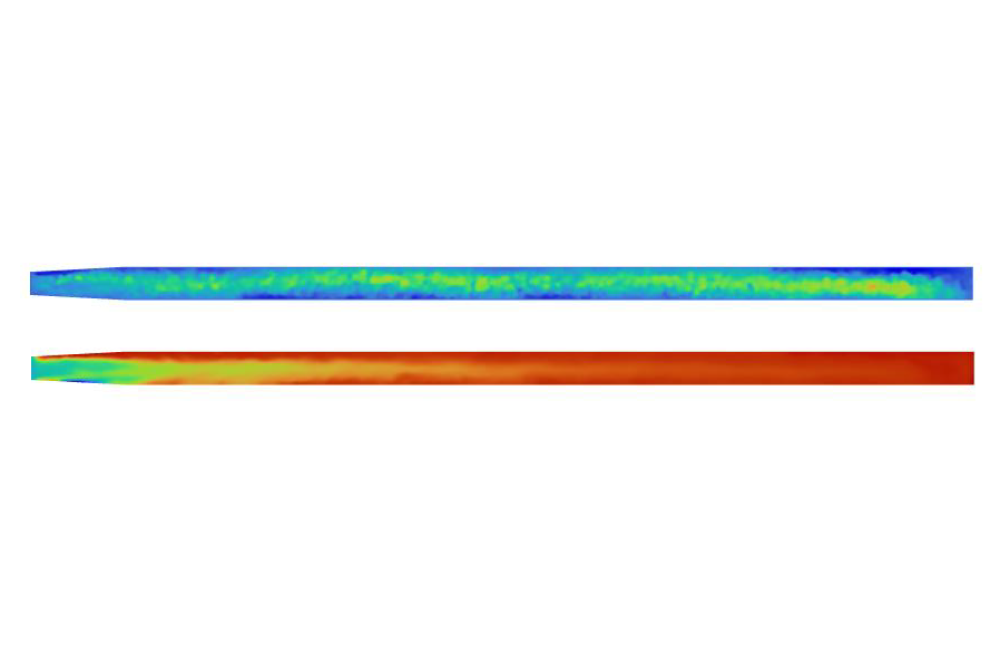

Simulation of DFBG gasification with waste wood pellets have been performed and validated. A circulating fluidized bed with a core-annulus flow structure was established in the reactor. At the bottom of the reactor a dense bed with high char content formed. In this area the majority of pyrolysis and gasification reactions take place. Due to the fast release of pyrolysis gases a clear influence of the position of the fuel feeding screw can be seen in the reactor thermodynamics.

Above the bed the homogeneous reactions are dominant. With increasing height and residence time the reactions approximate the equilibrium and leave the reactor close to equilibrium state.

Discussion

The key hydrodynamic parameters pressure drop and solid circulation were predicted accurately by the model while the solid inventory was somewhat underpredicted. This due to overprediction of the particle drag. To reduce this deviation state of the art EMMS model was used for drag prediction, research on these models is still ongoing and fully accurate results cannot be expected.

Gas species concentrations at the reactor outlet were generally in good agreement with experimental data with the exception of water which was overpredicted at cost of hydrogen. This is likely due to two factors. Moisture measurements in the experiments are influenced by tars in the system leading to uncertainties regarding the accuracy of the value used for validation. Furthermore the char content inside of the bed could not be determined during the experiments, which causes uncertainty in the boundary condition used in the simulation. Likely the estimation of the char inventory was too low and consequently the conversion of water through reaction with char to hydrogen was underpredicted.