Large Eddy Simulations of a Turbulent Iron Particle Jet

Einleitung

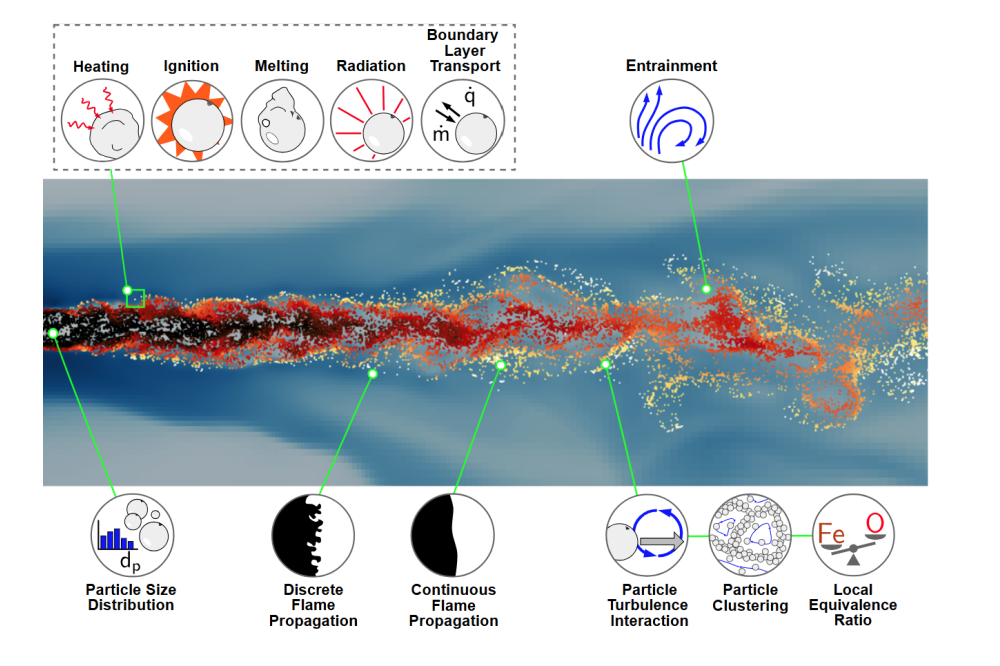

Iron powder is a promising carbon-free energy carrier due to its abundance, recyclability, and high volumetric energy density. Iron combustion is governed by heterogeneous oxidation of particles, strongly influenced by heat and mass transfer, fundamentally different from volatile solid fuels. This necessitates deeper understanding of the governing physics for effective burner design. While previous numerical studies of canonical setups advanced single-particle and simple flame understanding, industrial combustors involve significantly more complex fluid mechanics. This work numerically investigates a turbulent iron particle-laden jet with hot co-flow based on novel experiments. Cold jet flow carries iron particles, which ignite as hot co-flow gases are entrained into the shear layer. This configuration enables detailed analysis of early flame development and particle-turbulence interaction, the study's main objectives.

Methoden

The numerical simulations are conducted on a turbulent iron particle-laden jet issued into a hot co-flow. The injection lance provides a fully developed turbulent air-particle flow at ambient temperature, actively cooled by water, while the concentric co-flow is heated by an atmospheric microwave plasma. Besides the variation of co-flow temperature, the particle injection rate (PIR) is varied to study combustion characteristics at different particle concentrations. Large eddy simulations with Lagrangian parcels are conducted for this study. Separate precursor simulations are performed for the co-flow and the injection pipe flow to provide realistic inlet conditions. The resulting time-resolved velocity field and Lagrangian data are sampled and mapped to the jet inlet. Each iron particle is represented by a Lagrangian parcel. Two-way coupling, gravitational and drag forces are considered.

Ergebnisse

Turbophoresis causes particularly small particles to migrate toward the wall. The simulations qualitatively reproduce the trends observed experimentally and predicted in the literature. Particle accumulation at the injection pipe wall promotes the particles' ignition probability. Particles experience highly unsteady ambient conditions along their trajectories. This can lead to incomplete oxidation or to completely kinetic-limited oxidation, particularly for small particles, since slow oxidation at the beginning forms an oxide layer, which has a hindering effect on ignition. Most ignition events occur within the jet shear layer, where entrainment raises the local gas temperature, such that the particles' ignition temperature is achieved. At higher co-flow temperatures, ignition requires less entrainment, broadening the region where ignition can occur, while higher particle loading enhances local heat release. Both effects promote inter-particle heat transfer and contribute to a more efficient ignition. Once a sufficient number of particles ignite through entrainment, the resulting heat release enhances additional particle ignition via inter-particle heat transfer. This cascade mechanism can transition the system from isolated ignition events to a collectively sustained reaction, thereby improving the overall ignition efficiency. No correlation is found between the degree of clustering and the ignition probability, because the optimal Stokes number for particle clustering differs from that for entrainment-induced ignition.

Diskussion

Particle clustering already occurs in the injection pipe, before particles enter the combustion region. Entrainment of the hot co-flow into the particle-laden jet is the key mechanism for iron particle ignition. An increase in co-flow temperature or particle injection rate promotes ignition through inter-particle heat transfer and leads to an increase in the ignition ratio within the region of interest. Enhanced entrainment-induced ignition triggers a cascade-like, self-reinforcing process. Particle clustering plays a minor role before the jet is fully mixed with the surrounding. Preferential concentration becomes relevant only after complete mixing, when the resulting conditions permit particle ignition. An optimal range of Stokes numbers exists for enhanced mixing between particles and hot gas, leading to ignition. This study demonstrates the complex interplay of multiple mechanisms governing turbulent iron particle-laden flows. Future investigations should explore the effects of varying gas compositions and incorporate additional physics, such as inter-particle radiation and particle evaporation. Additionally, the dependence of the optimal Stokes number range on other parameters, including Reynolds number and particle size distribution, requires investigation. Finally, laboratory-scale reactor studies should validate the findings and analyze their impact on overall iron conversion efficiency. Furthermore, such studies can assess the effectiveness of the proposed design strategies.