Development of Methods for the Simulation of Technical Combustion Systems

Einleitung

The design and the optimization of modern combustion devices represents challenging tasks where complex physical processes such as the heat transfer, the underlying turbulent flow field as well as the pollutant formation need to be considered. Current trend in operation of industrial gas turbines and aero-engines implies using the lean-premixed burning conditions aiming at the reduction of the harmful emissions and efficiency improvement. This leads to an increasing usage of computational methodology, which allows detailed insight into combustion physics and processes controlling the emission formation. The permanent increase of computer resources has ensured that the large eddy simulation (LES) rational becomes a commonly used computational tool for complex turbulent applications, including both reacting and non-reacting flows. This project focuses on development and assessment of combustion models in context of LES and configurations relevant for technical combustion devices.

Methoden

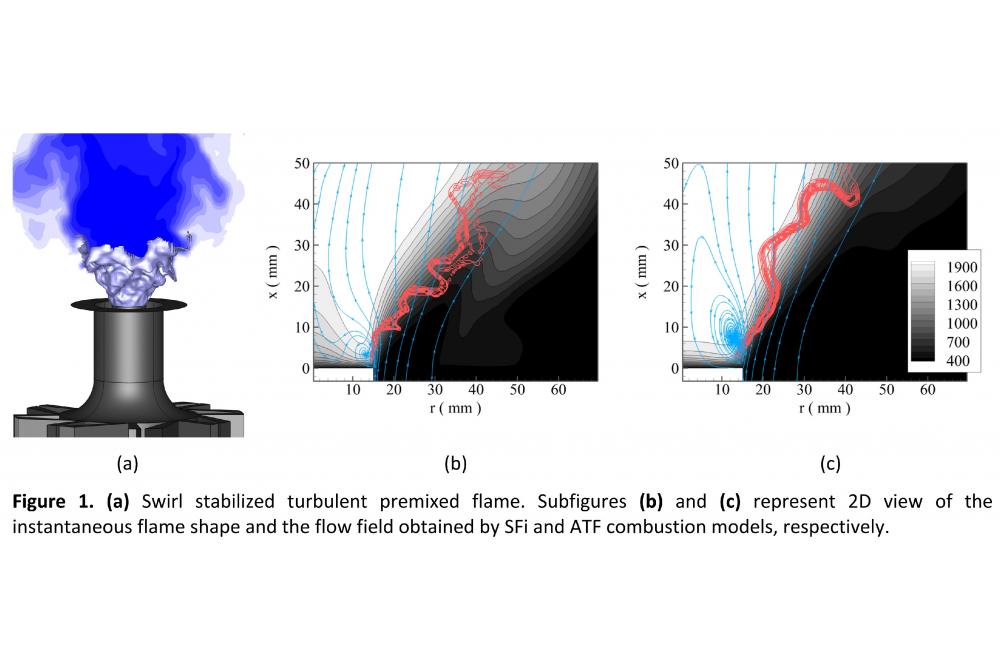

Within this work, the simulation of turbulent combustion is realized in two steps. The first step aims at describing detailed reaction chemistry by a small number of transported controlling variables using tabulation. The approach chosen is based on the tabulation of precomputed thermochemical states to account for the relevant physics of the flame during the simulation. In the second step, modeling approaches need to be employed in order to recover the sub-grid turbulenceflame interaction on the coarser grids, commonly used in simulations of complex geometries. Herein, two different combustion modeling approaches are developed and assessed, i.e. artificial thickening of the flame front (ATF) and Eulerian Monte Carlo stochastic field (SFi) method. The conjunction of developed methods with the FGM chemistry description approach is expected to increase the predicting capability of the individual methods as well as significantly reduce the computational costs associated with the simulation of complex combustion devices. The application investigated within this work features a swirl stabilized turbulent premixed flame, which demonstrates a typical flame stabilization strategy found in industrial burners (see Fig. 1a). The simulations have been conducted with academic code FASTEST, which is extended and adopted for the simulations of turbulent reactive flows.Figure 1b and 1c illustrate the instantaneous flame shape and the underlying turbulent flow field predicted by the two models developed.

Ergebnisse

Both approaches have been validated using available experimental data, whereby the resulting investigation revealed and quantified the different model sensitivity to the underlying physics of the flame. Furthermore, the conducted simulations allowed detailed insight into physics of the investigated burner, being beyond the reach of the experimental techniques. Within this project the development of joint ATFFGM and SFi-FGM modeling approaches have been conducted, where detailed assessment regarding the predicting capability of the approaches has been addressed.

Diskussion

The results obtained have demonstrated the capability of both methods in handling premixed turbulent flames within complex configurations. Further work will include extension and evaluation of the implemented methods for prediction of more complex physics in technically relevant applications, e.g. non-premixed and partially premixed flames, local flame extinction, and flame stratification.