Large Eddy Simulations of Lean Partially Pre-vaporized Turbulent Spray Flames

Einleitung

Lean Partially Pre-vaporized (LPP) turbulent spray flames stand out as a promising technology to reduce the emission of NOx and the maximum temperature for combustion engines.[1] Because of the partial pre-vaporization and the resulting lean partially premixed mixture the LPP flame fronts are able to propagate into the combustion chamber. The correct computation of the turbulent flame propagation is a challenging task for practical purpose applications.

Methoden

For these cases, Direct Numerical Simulation (DNS) are not feasible and the usage of a modelling procedure to capture the effects of the turbulence-flame interactions based, for instance, on Large Eddy Simulation (LES) is necessary. Typically, when a liquid spray is injected directly into a combustion chamber the high evaporation rate of droplets delivers a high concentration of fuel vapor close to the nozzle. This mixture quality leads to a predominance of reactive processes similar to those found in gaseous non-premixed flames. Based on this characteristic, combustion models originally developed to non-premixed flames have been modified to compute turbulent spray flames. On the other hand, in LPP burners the spray is not integrally introduced in the combustion chamber, in reality a mixture of fuel vapor and liquid structures is injected instead. As a consequence regarding the quality of the resulting mixture the flame structure is expected to be controlled by the flame propagation speed rather than by the diffusion of reactants and products. Accordingly, to capture this aspect better analysis on the extension of a single phase premixed flame model are performed in the present investigations. To investigate the structure of propagating partially pre-vaporized spray flames, in this work an Eulerian-Lagrangian spray module relying on the Artificially Thickened Flame (ATF) framework coupled to the Flamelet Generated Manifold (FGM) chemistry reduction method is developed. A detailed mechanism of n-heptane including 88 species and 387 elementary reactions is adopted to correctly address the chemical reactions. The unsteadiness arising from turbulent dispersion of evaporating droplets are captured by the LES method. An evaporation model based on the non equilibrium approach is applied to describe droplet evaporation process. Three of the LPP n-heptane spray flames investigated experimentally in [1] are selected to validate the proposed module.

Ergebnisse

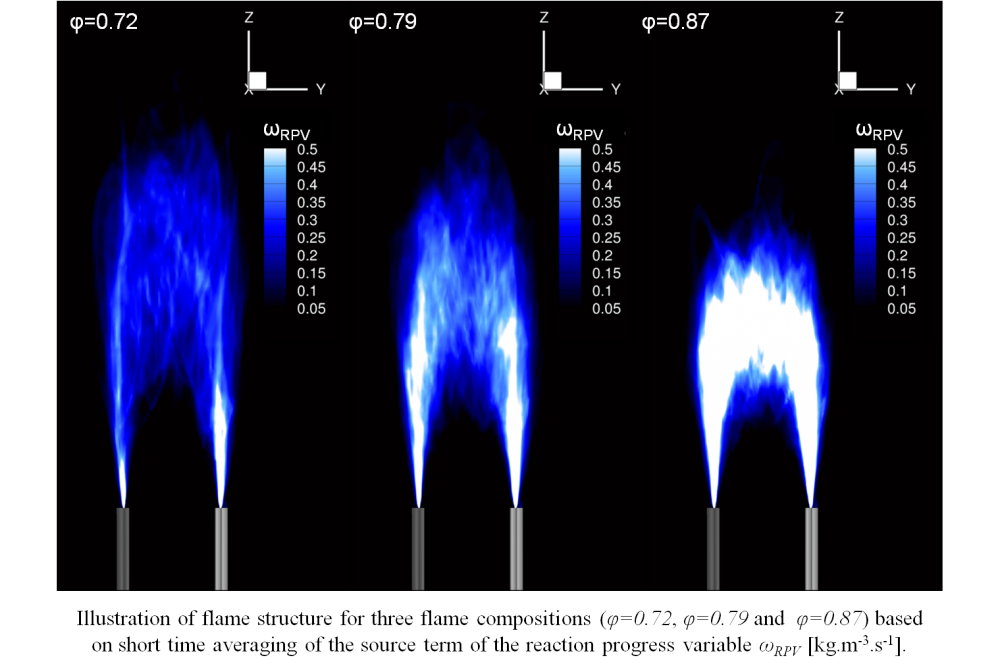

The success of the achieved results could demonstrate the effectiveness of the modeling approach. To illustrate it, the structure of the three chosen turbulent flames are exhibited by the figure through short time averaging of the source term of the reaction progress variable (ωRPV). The decrease of the flame length according to the increase of the equivalence ratio (φ), also observed experimentally, is correctly reproduced. This phenomenon is a particularity of lean propagating flames which is related to the reduction of the flame speed due to the increase of the equivalence ratio.