Machine Learning Application in Automotive Catalysts

Einleitung

The computational resources of the Lichtenberg HPC were used in this project to train physics informed machine learning (ML) models. The HPC enabled us to train multiple Neural Networks (NN) in parallel. These models were used, as written in the project proposal, to model automotive catalytic converters in the framework of the KIARA project funded by the BMWK. These networks are promising to function as surrogate model and speed up the calculation speed in comparison to physical simulations.

Methoden

The NNs for this project are developed in Python with the usage of the PyTorch library. This library allows flexible structures for the individual layers, which is necessary for researching different architectures. The training data are generated with an existing physical simulation running in Fortran and Matlab.

In addition, it was expected that the usage of GPUs would increase the training process, which was not the case for the small NNs used in this work. Therefore, the training was carried out on CPUs. Thanks to the Lichtenberg HPC, the model development could still be accelerated significantly due to parallel training on multiple CPU cores, which allowed us to compare different architectures in a short time period.

Ergebnisse

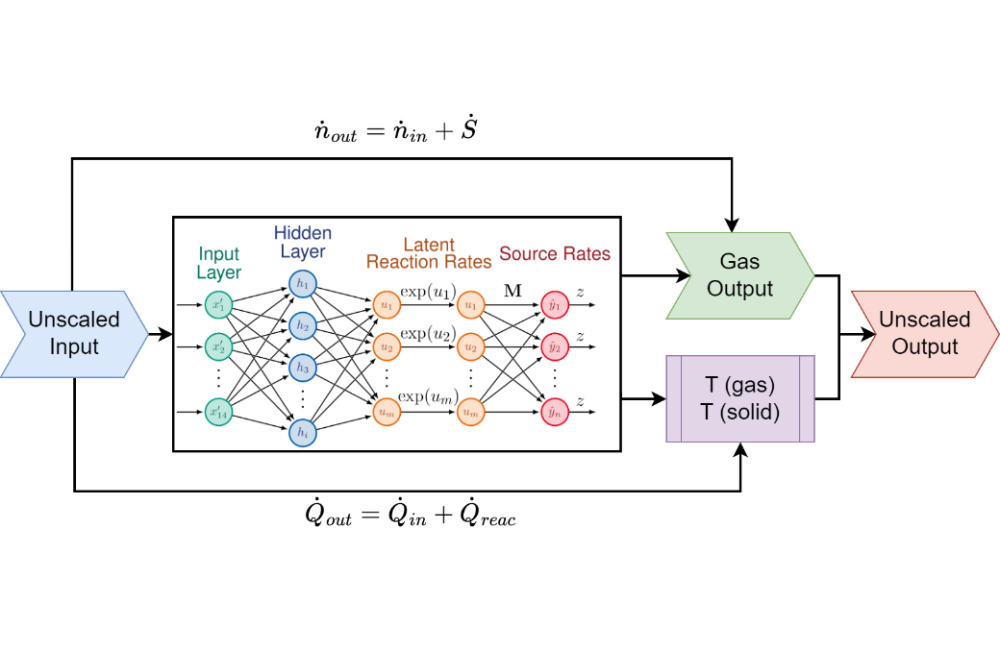

The target for this project is the development of NNs enhanced with chemical and physical information. Therefore, different model architectures were tested. Due to large number of hyperparameters for the training process and the model itself, parallel computation is mandatory to optimize the neural network. It was found that the usage of chemical constraints leads to more robust models. These constraints can include e.g. mass balance or energy conservation. A schematic framework of the models is shown in Figure 1. By including chemical information, it is possible to use smaller networks with only 3 layers containing each 25 nodes to represent complex correlations.

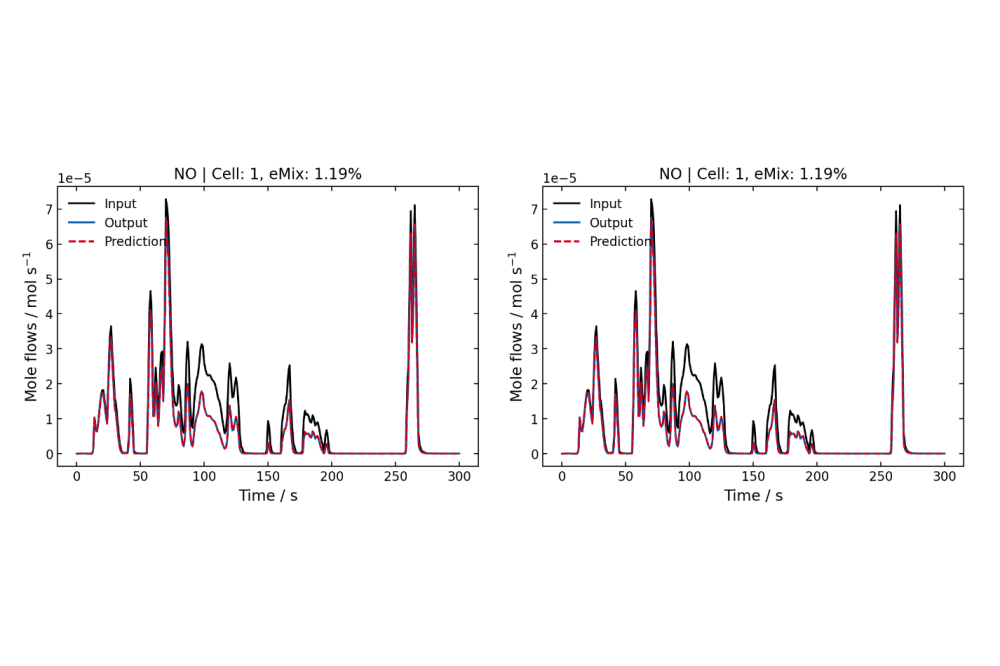

The graphs depicted in Figure 2 show automotive driving cycles before and after a Selective-Catalytic- Reduction (SCR) converter. The goal is to convert toxic species like nitrogen oxides (NOx) to harmless nitrogen (N2). The reduction is enabled by adding ammonia (AdBlue®) before the catalyst. The trained model represents several reactions taking place on the active sites including the surface coverage of ammonia, which is crucial for the conversion of the nitrogen oxides. The challenge for those driving cycles is the transient behavior. These transient cycles could be predicted with the newly developed models with deviations around 1% regarding the original training data.

Diskussion

The results show that feed-forward neural networks are capable of learning the behavior of automotive catalysts in combination with chemical constrains. At the moment it is still a challenge to apply the NNs on different cycles and engine types. Future work will focus on better generalization of the neural networks and higher speed-up factors. These are necessary steps for a full publication, which is in preparation.