Molecular Dynamics Simulations of Nanoglasses

Einleitung

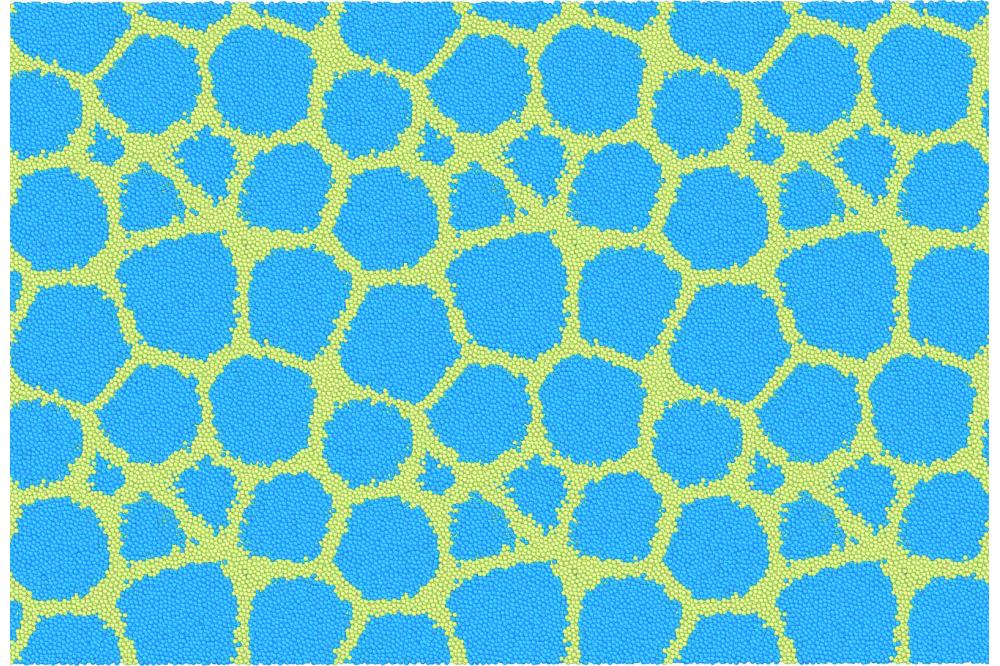

Metallic glasses (MGs) are of great technological interest because of their high strength and hardness [1]. However, when MGs are exposed to an external load then they fail catastrophically along a single shear band [2]. On a microscopic scale, shear bands in MGs are considered to be controlled by the activation of shear transformation zones that represents local shearing of approximately 100 atoms [3]. To avoid the catastrophic failure in MGs and improve their ductility, predeformed samples and glasses with nanocrystalline inclusions have been studied in the past [3,4]. The main findings of these studies is that the presence of such microstructural inhomogeneities in the samples prevent the formation of the shear band, which could cause catastrophic failure. Recently, a new class of MGs have been proposed, the so-called metallic nanoglasses (NGs) [5]. Metallic NGs have been produced by consolidating nanometer-sized glassy spheres which are prepared by inert-gas condensation [5,6] (Fig. 1). Recent experimental studies have shown that metallic NGs present enhanced ductility [5] and ferromagnetism [7] when compared with MGs. In addition, NGs are promising candidates as materials for medical applications [8].

Methoden

The properties of materials are strongly controlled by their microstructure. Despite the improved properties of NGs, their microstructure is not well understood. Atomistic simulations are useful tools to gain insights on the atomic level into the structure of a material. Several microstructural models for NGs have been proposed based on atomistic simulations. Although those models have offered explanations on the origin of enhanced ductility in NGs, a proper structural model which could explain the experimental observations on the structure of NGs is still lacking. We have performed large-scale molecular dynamics simulations, as implemented in the LAMMPS software [9], to investigate the microstructure of the NGs.

Ergebnisse

Our results reveal that NGs are amorphous materials with inhomogeneous microstructure which consists of glassy grains connected with glass-glass interfaces (Figure). Structural analysis show that the glass-glass interfaces in NGs are characterized by a lack of short range order compared to MGs and a width of about 1 nm. In addition, they have a different composition than the glassy grains. The present microstructure for NGs is consistent with experimental analysis by means of small-angle X-ray scattering measurements and element mapping data on the Sc-Fe Ngs [5].

Ausblick

In the future, we plan to perform molecular dynamics simulations to study the deformation mechanisms in NGs. It is proposed that the glass-glass interfaces prevent strain localization. We will perform a set of mechanical tests in order to a get better understanding on how glass-glass interfaces in NGs influence their mechanical properties.