Probabilistic Power Plant Dispatch Prediction

Einleitung

To model future energy systems and their markets, it is important to understand the underlying dynamics of their components correctly. Common fundamental market models simulate power plant dispatch and rely on expert guesses for their parametrization. This is a significant source of uncertainty regarding the model results.

Methoden

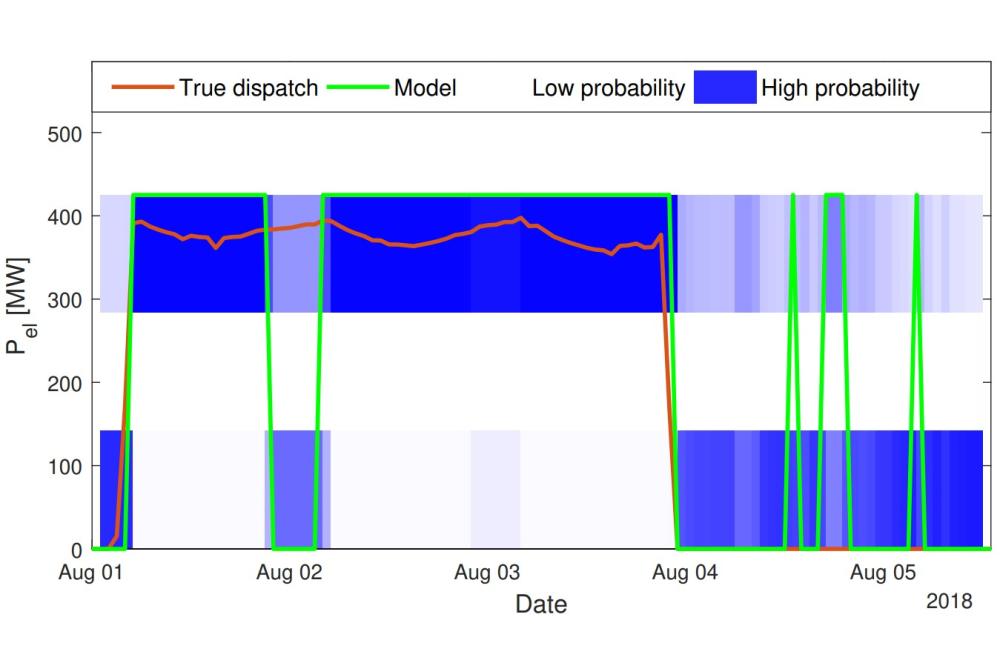

We proposed a method to predict the dispatch of power plants probabilistically, based only on historic open data. We use published operational data of the power plant as well as electricity and fuel market prices. These are fed into a fundamental dispatch model as part of a Monte Carlo simulation to obtain probabilistic estimates of the dispatch parameters. Additionally, we obtain probabilistic dispatch predictions from the derived probability distributions over the parameter values. We determine the posterior predictive distribution which takes the uncertainty about the power plant parameters into account.

Each Monte Carlo step includes solving a Mixed-Integer Linear Program which takes on average about 3 seconds. Since the samples are taken independently, all optimization problems can be solved in parallel. The HPC therefore reduces overall computation time drastically in comparison to that on a single machine, which would be up to three months.

Ergebnisse

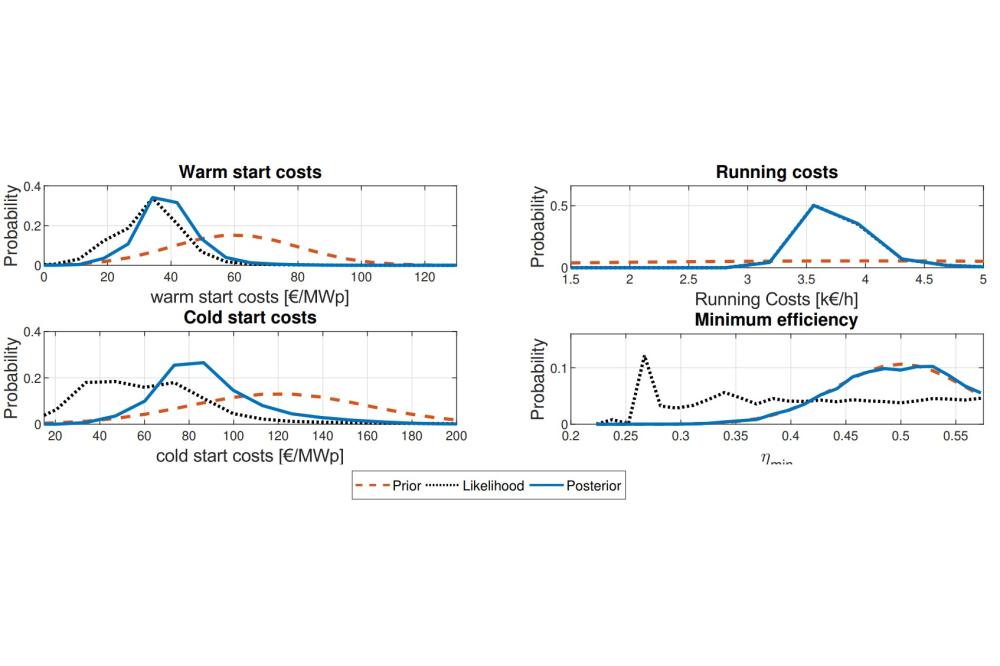

We applied this method to three German natural gas combined cycle power plants and infer the cold and warm start costs, fuel independent running costs, the efficiency at minimum load, and the warm-keeping time, that is, the time after which higher cold start cost are induced by the start up procedure. Our approach increases the prediction accuracy in comparison to deterministic parameter estimation and additionally yields further information on the certainty of the dispatch parameters. The results showed that warm and cold start costs are considerably lower than expert’s guesses suggested. For the efficiency at minimum load out approach could not infer new information.

Diskussion

We showed that the probabilistic models had overall higher accuracies than the deterministic model, when considering the highest probability prediction. However, the increase in accuracy is small. One has to decide depending on the use case whether this is worth the increase in required computation time. Furthermore, the probabilistic prediction gives a measure of certainty to the predicted dispatch. We observed that the prediction is less certain in hours in which the deterministic dispatch was inaccurate. This additional information in the model results might increase the trust in the prediction.

In future research this model could be expanded to include more different power plant technologies, e.g. hard coal and lignite power plants. However, most power plants in Germany are combined heat and power plants and applying the model to them is currently not possible because heat production data is not published. Furthermore, this prediction model could be applied as part of an energy system model. There the results of the parameter inference could be used as parameters of underlying fundamental dispatch models.