Structure-Property Relationships in Metallic Glasses

Einleitung

The current limits of metallic glasses are tied to their brittle behavior at room temperature [1]. To overcome brittle failure of metallic glasses heterogeneities ranging from crystalline inclusions [2] to structural heterogeneities with scales from a few nanometers to tens to hundreds of micrometers [3] are synthesized. The structural and stress flcutuations affect the propagation of shear bands (SBs) and promote SB multiplication [4,5]. The complex dynamics of shear banding are typically difficult to study because of the spatial and temporal confinement [6]. Additionally, given to the amorphous nature of metallic glasses, even the most sophisticated methods based on atomistic simulations and machine learning frameworks could not perfectly characterize the relationship between heterogeneities and deformation mechanisms and, hence, establish a universal structure-plasticity picture [7].

Methoden

The atomic-scale deformation mechanisms of monolithic Cu64Zr36 metallic glass (MG) was investigated by performing molecular dynamics (MD) and athermal quasi-static (AQS) simulations using the LAMMPS software [8]. The deformation mechanisms were monitored using atomic the local entropy-based structural identification, von Mises strain and stress and the sign of rotation angle calculated and visualized using the OVITO analysis and visualization software using the python scripting interface [9].

Ergebnisse

The main goal of this project was to understand the correlation between atomic-scale deformation processes and the structural evolution in monolithic metallic glasses. Monolithic MGs generally show nearly zero ductility at room temperature due to the highly localized nature of the deformation process [2]. To overcome the brittleness of MGs, the atomic structure, chemistry or loading conditions are usually controlled [10]. A very effective strategy to attenuate the brittleness of MGs is the introduction of structural heterogeneities in terms of harder (denser) and softer glassy (rejuvenated) regions. Here, structural fluctuations, in terms of topological disordering in the soft phase, perturb the STZ percolation process and hinder the formation of critical shear bands. Since the propagation of a shear band is a stress-driven process the deformation behavior of MGs has been controlled by modulating their internal stress state. The elastically designed MG heterostructures provide enhanced ductility together with strain-hardening during tensile deformation. The stress gradient leads to the formation of many shear bands that consequently enhance the macroscopic ductility of MGs. Additionally, residual compressive stresses significantly increases the strength of the glass and, is responsible for the observed strain-hardening. Finally, the atomic-scale origin of the observed variations in the SB dynamics and angle with changing the structural state was revealed.

Diskussion

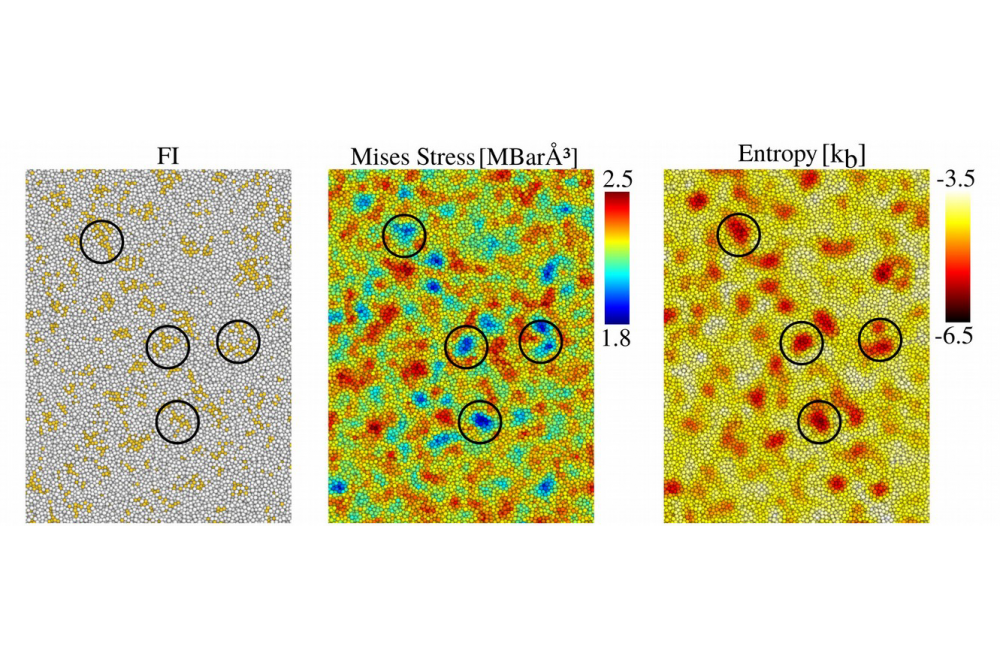

Although the structural disorder of MGs entails the absence of structural features such as grain and phase boundaries, dislocations and stacking faults, they possess a high degree of short-range order (SRO) and even medium-range order (MRO). Hence, down to the atomic level, MGs show heterogeneous structures charachterized by high ordered clusters, full icosahedra (FI), and more unfavorable polyhedra, which are needed to fill the spaces between the more ordered clusters and to connect the backbone structure (Fig. 1a). The von Mises stress in the FI close-packed clusters is significantly lower compared to the surrounding (see Fig. 1b) and, in general, local stress fluctuations correlate with the local structure. In the case of Cu64Zr36 metallic glass areas of low local entropy correspond to FI clusters, while the liquidlike clusters (non-icosahedral) have high entropy (see Fig. 1 c). Under load, the shear band follows the path of lower order and high entropy. Moreover, when the shear band approaches higher ordered regions of low entropy, shear deflection and branching occur promoting shear band multiplication. While the local entropy parameter shows an excellent ability to describe the complex spatio-temporal strain distribution process, the evolution of elastic fluctuations identified by von Mises stress calculation allows predictions on the shear band direction and the propensity for activation and propagation prior to yielding. The von Mises stress precedes the shear band path and leads to the evolution of the shear band at a certain place and direction.