Numerical Simulation and Analysis of Wetting Phenomena in Inkjet Printing

Einleitung

Droplet impingement and spreading are of particular relevance for various technical applications, including inkjet printing. The small length scales of only a few microns, however, pose a limitation to experimental observations. Therefore numerical simulations of droplet impingement, spreading and coalescence are conducted within the scope of this project. Special focus is thereby put on the interaction between heat and species transport processes on one side and the wetting process on the other side.

Methoden

To gain a better understanding of the underlying transport processes, numerical simulations of droplet spreading with coupled surfactant transport were performed during the first period of the project. The two-phase flow is described using the algebraic volume of fluid method implemented in the open source CFD library OpenFOAM. The contact line dynamics are modeled using a hydrodynamic subgrid scale model. Furthermore, the two-phase flow solver was extended to account for the transport of soluble surfactants using a two field approach. By including the Marangoni stress term in the momentum balance in conjunction with a suitable equation of state relating the local surface tension to the surfactant conentration, the influence of species transport on the wetting dynamics is taken into account.

Ergebnisse

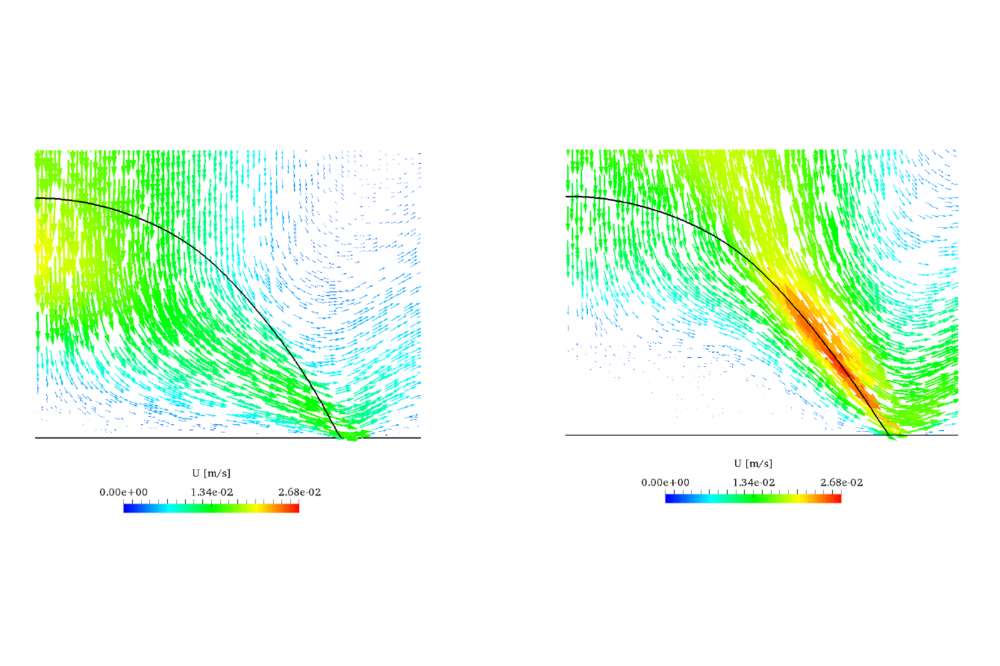

First results indicate a strong influence of the Marangoni effect on the flow profile within a surfactant laden droplet, especially in the early stages of spreading in the capillary/viscous regime. This is illustrated by figure 1. The change in the flow profile affects the overall spreading dynamics and therefore the droplet diameter at a given time. Furthermore, the results show that the change in interfacial area during droplet spreading can lead to a thinning of the surfactant concentration and therefore an increase in surface tension. This behavior is quite obvious for insoluble surfactants. Depending on droplet size and initial surfactant concentrations, however, this behavior was also observed in numerical simulation with soluble surfactants.

Diskussion

The results from the past project period proved the numerical method suitable to study coupled wetting and species transport processes. Furthermore, our extensions to the flow solver regarding species transport have successfully been tested in the High Performance Computing environment. While we focused mainly on the spreading of single droplets until now, we plan to extend our investigation to single droplet impingement as well as (off centered) droplet collision and coalescence. These highly dynamic processes require high temporal and spacial resolution and therefore make the use of a High Performance Computer indispensable.