Ductile Shape Memory-Amorphous Nanolaminates

Einleitung

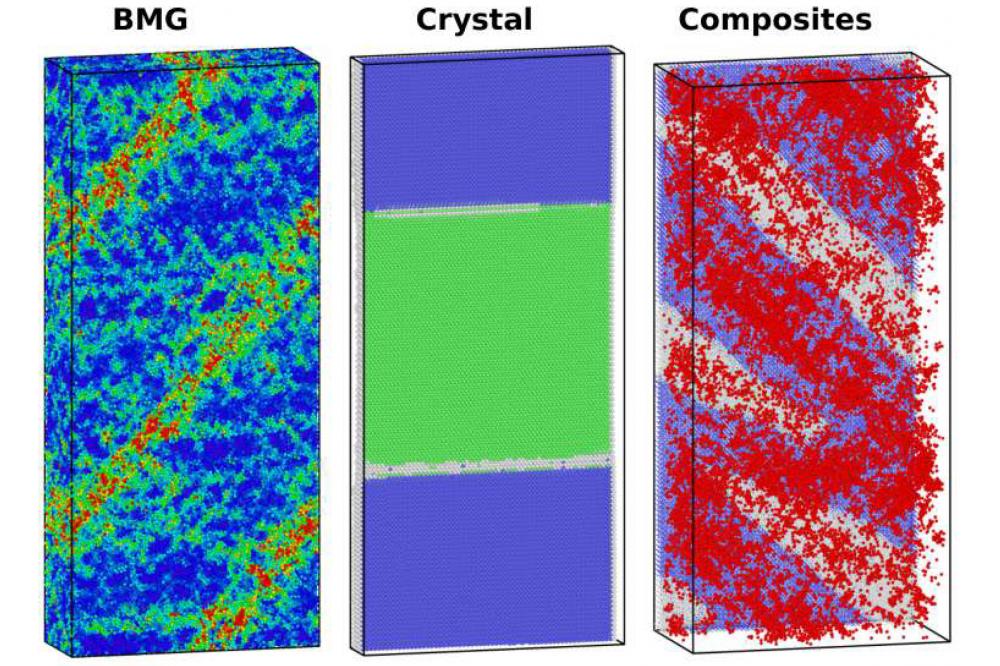

We model the deformation behaviour of metallic amorphous/crystalline nanolaminate systems using molecular-dynamics computer simulations. Amorphous-crystalline nanolaminates with shape memory alloys may be a material class which is combining the advantageous properties of metallic glasses with large-strain homogeneous flow at low temperatures and highstresses. Therefore, tailoring the architecture of metallic glass laminates with shape memory phases may allow to develop materials with very large tensile ductility.

Methoden

The lack of macroscopic tensile plasticity at room temperature precludes the extensive use of metallic glasses in engineering applications despite their high strength and large elastic limit. A reasonable tensile strain capacity, up to 14 %, is observed in amorphous-crystalline nanolaminates. In order to avoid detrimental run-away shear propagation and ensure shear band arrest, however, the crystalline layers must be sufficiently thick and, thus, occupy an overall volume fraction larger than 80%. For having the full benefit of the superior properties of metallic glasses; however, one should rather consider nanolaminates, in which the volume fraction of the glassy phase is the dominant one. Metallic glass composites reinforced with shape memory crystals deformed under tension show an enhanced plasticity and also an overall work hardening. Hence, we investigate the deformation behaviour of metallic amorphous/crystalline nanolaminate systems using molecular-dynamics computer simulations. Laminates with different volume fraction and thickness of shape memory phase was constructed.

Ergebnisse

We found that laminate composites with a low fraction of shape memory layers (below 45 vol. %) experience enhanced tensile ductility and nearly ideal plastic flow behaviour. The exceptional deformability originates from the very complex deformation behaviour, a result of a large number of effects related to the martensitic deformation in the shape memory phase and confinement effects. Our work has provided an atomistic description of the competing and mutual processes of martensitic transformation and shear band formation and shear band dynamics in laminate composites. Therefore, one can predict that amorphous-crystalline nanolaminates with shape memory alloys may be a viable route for developing new materials with large-strain homogeneous flow of metallic glasses at low temperatures and high stresses.