Bildunterschrift

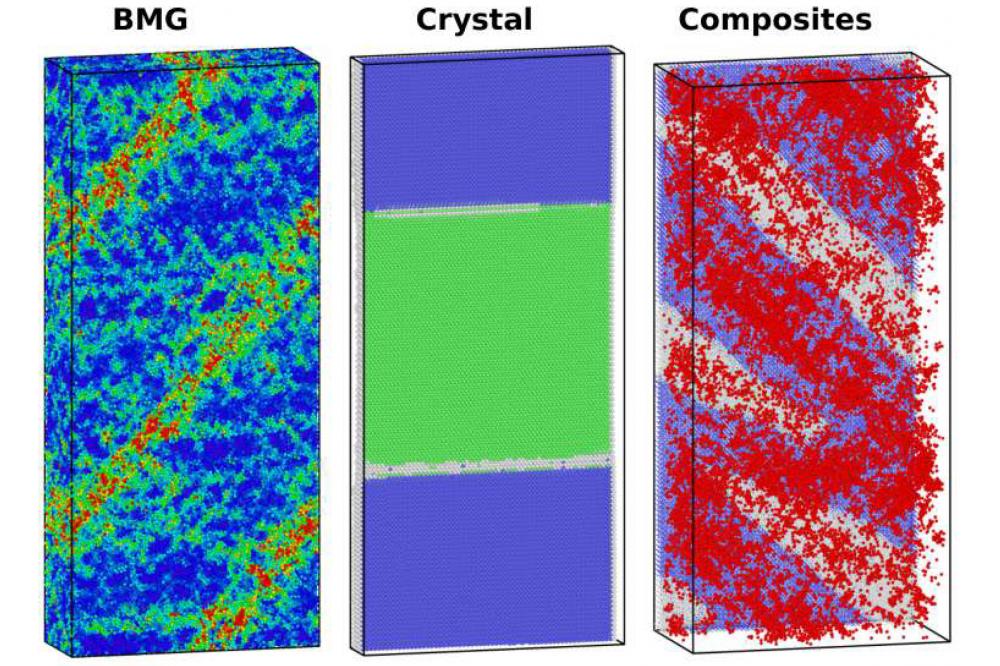

Figure 1: Deformation mechanism of a bulk metallic glass (BMG) (a), a shape memory CuZr crystalline plate (b) and a laminate structure formed by joining both of them (c). The colour scale in (a) indicates the variation of the atomic shear strain from 0.1 to 0.8. The panel (b) shows the results of the CNA in the plastically deformed crystalline plate. To visualize the competing deformation mechanism in the laminate (c) only glassy atoms with a local shear strain higher than 0.2, which indicate STZs, are displayed.