Additive Manufacturing of Magnetic Materials using Functionalized Nanoparticles: Insights from Molecular Dynamics Simulation

Einleitung

Laser powder bed fusion is an additive manufacturing technology involving a gradual build of layers to form a complete component typically starting with a powder. The high energy density of the laser creates specific thermal histories in the material, which tends to produce grain structures. Since Fe-based materials with nanoscale compounds exhibit a distributed magnetic transition, which leads to broader magnetic entropy curves with better magnetocaloric refrigerants, printing such FeNi structures offers the possibility to tailor appropriate microstructures.

Methoden

We compare different scenarios namely prealloyed nanoparticles and powder blends of elemental nanoparticles on a FeNi support layer. The formation and evolution of defects and grain structure during laser powder bed fusion is investigated experimentally and numerically. The results of atomistic simulation with calculated grain boundaries energy and mobility can serve as input for phase field simulations. This approach presents the capability of exploring the impact of laser powder bed fusion processing parameters on microstructure and magnetic properties. The validated simulated polycrystal texture also forms the fundament of the subsequent magnetic hysteresis simulation on laser powder bed fusion-processed structures.

Ergebnisse

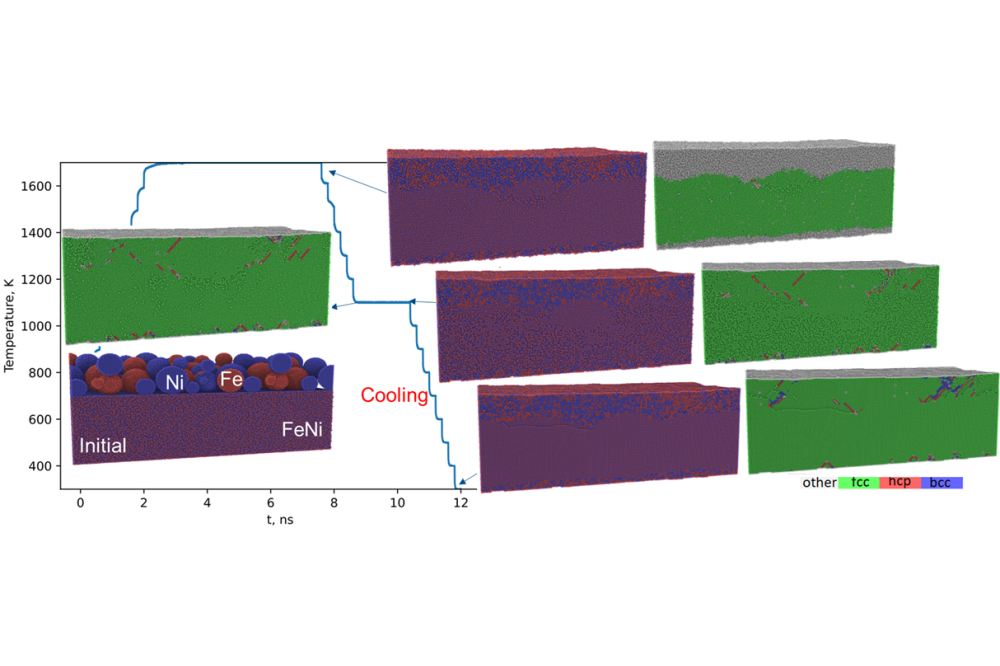

We ran a sequence of MD simulations, where we explore the possibility to print FeNi alloys from powder blends and prealloyed particles. We are focusing on the first premelting stage, when the powder is indirectly heated by the heat wave in front of the laser spot. We analyze the intermixing and liquid-solid transitions as well as the characteristic time scales for interdiffusion, wetting and solidification. In the case of powder blend on a FeNi layer, a chemical inhomogeneous and dense layer is obtained, which is massively defective. We observe cluster formation in the zone with higher Fe content. Slight surface segregation is observed for the component with the lower surface energy (Fe). Simulations of the laser impact in a blend of elemental nanoparticles do not lead to complete intermixing, since the lifetime of the liquid is too short. Although pre-alloyed powder reduces the risk of inhomogeneity in built material, blended powders can be used to assess the printability and properties of novel alloys in laser powder bed fusion.

Diskussion

Dense, smooth pore free layers with inhomogeneous element distribution and a high density of lattice defects, such as stacking faults, twins, and vacancies are formed if a supported powder blend is heated from the heat wave advancing the laser spot. Our results reveal that the formation of the intermetallic L10 phase is massively hindered by the fast kinetics in the laser powder bed fusion process due to surface effects, local off-stoichiometry and fast solidification. The complete intermixing of the molten stage is not possible during a single laser shot even on the nanoscale.